What is the best way to make soybean oil? Why?

September 2, 2021 18:00/ FAQ/ leave a messageIn general, there are two ways to make soybean oil from seeds. One is press way and the other is puffing & solvent extraction way. Without taking into account external factors such as daily processing capacity and capital investment, the puffing & solvent way is the best way to make soybean oil. The oil content of soybean is very low, about 15−20%. By using this way, the oil residue will be lower than 1%. It can achieve large output and high economic benefits. While the the oil residue of press way is about 7-8%, which causes oil losses to a certain extent.

Then, what is the process of making soybean oil by puffing & solvent way? Next, Henan Glory will do a simple introduction.

The process of making soybean oil by puffing & solvent way as following shows:

Soybean--cleaning--crushing--flaking--puffing----drying--solvent extraction plant--crude soybean oil refining plant

Soybean oil making machine

Soybean oil making machine

Firstly, the soybean through cleaning, crushing, flaking and puffing processing process to reach the best state before entering the solvent extraction plant. It can ensure us get more soybean oil. Secondly, the processed soybean cake will be sent into solvent extraction plant. Through soybean oil extraction, wet meal desolventization, mixed oil evaporation and stripping and solvent cooling and recycling steps to obtain more crude soybean oil.

Solvent extraction plant

Solvent extraction plant

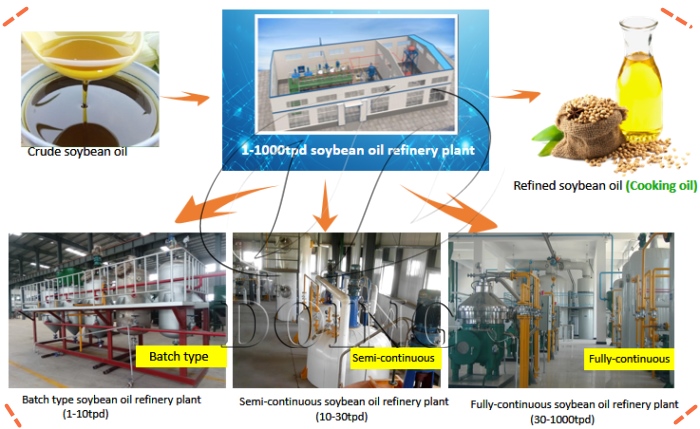

Last but not least, the crude soybean oil can be sold in the market or be sent into refining plant to get rid of the harmful impurities and needless impurities, aims at obtaining standard quality soybean oil.

Soybean oil refinery plant

Soybean oil refinery plant

As a professional soybean oil processing machine manufacturer, Henan Glory Company can customized various kinds and configurations of soybean oil processing machine for you. Tell us your requirement, we will give you the free quotation.