Complete set of groundnut oil making machine

Small, medium, large scale groundnut oil processing equipment

Small, medium, large scale groundnut oil processing equipment

Groundnut oil making machine is the main machine to produce groundnut oil. The full set of groundnut oil making machine mainly includes: groundnut oil pretreatment machine, groundnut oil solvent extraction plant and groundnut oil refinery plant. As a professional manufacturer of groundnut oil making machine, we always offers high quality machinery and most competitive price!

Usually, we use pressing methods to extract groundnut oil. After pre-pressing process, the oil residue in cake will be about 15%. In order to get more groundnut oil, the groundnut oil solvent extraction plant is necessary, after solvent extraction plant the oil residue in meal will be less than 1%. No matter the crude groundnut oil is get by pressing method or solvent extraction method, it all need to be refined by the Groundnut oil refinery plant. The main purpose of groundnut oil refinery plant is to separate the impurities in the crude groundnut oil. After refining, the oil can meet with first grade GB standard.

Introduction of complete set of groundnut oil pretreatment and prepressing section:

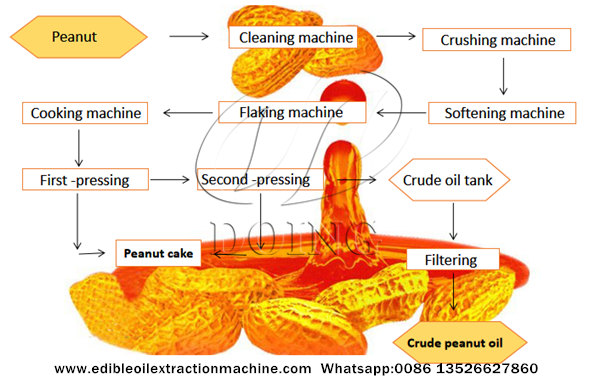

Pretreatment and prepressing section is the basic parts for a groundnut oil making machine. This section includes: cleaning, crushing, soften, flaking, roaster etc. All these groundnut pretreatment process can adjust the groundnut seed into the best condition for oil pressing, easy to press oil out and easy for next production section.

Process flow chart of groundnut oil pretreatment and pressing machine:

Groundnut oil pretreatment and pre-pressing process

Groundnut oil pretreatment and pre-pressing process

Groundnut oil pretreatment and pressing machine pictures show:

Groundnut oil pretreatment and pressing machine

Groundnut oil pretreatment and pressing machine

Introduction of complete set groundnut oil solvent extraction plant:

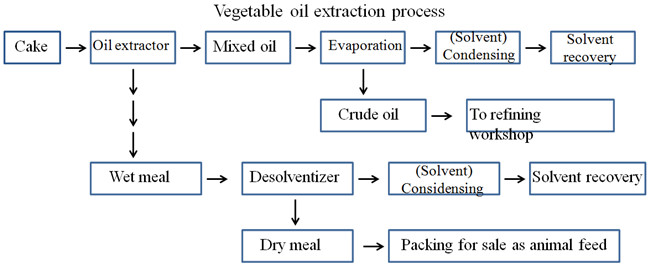

Solvent extraction section is the second part of groundnut oil making machine.This solvent extraction section includes: extraction system, D.T.D.C system, miscella stripping system, cooling and recycle system. After these process you can get most oil out from groundnut cake.

Process flow chart of groundnut oil solvent etxraction:

Groundnut oil extraction process

Groundnut oil extraction process

Groundnut oil solvent extraction plant pictures show:

groundnut oil extraction machine

groundnut oil extraction machine

Introduction of complete set groundnut oil refinery plant:

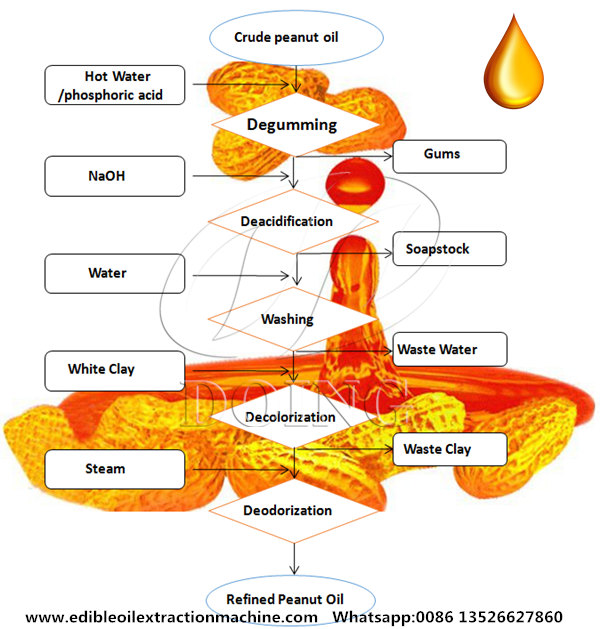

Refinery section is one of the most important process of groundnut oil making machine.This section mainly includes:Degumming, Deacidification, Decolorization and Dodorization etc. With the help of these processes, we can easily remove the hazardous substances and useless dross, to get the GB standard oil.

Process flow chart of groundnut oil refinery :

Groundnut oil refinery process flowchart

Groundnut oil refinery process flowchart

Groundnut oil refinery machine pictures show:

Various types groundnut oil refining machine

Various types groundnut oil refining machine

We Henan Doing Comapny can offer edible oil mill plant solutions for various oilseeds, such as flax seeds, tea seeds, palm kernels, copra, coconut, sunflower seeds, sesame seeds, soybeans, peanuts, cotton seeds,canola/rape seeds,mustard seeds, castor, corn germ, rice bran, etc. According to the different characteristics of different raw materials, our engineers could design specifically edible oil mill plant solution for each customer.

If you feel interest in our complete set of groundnut oil making machine, feel free to get in touch with us anytime.