Peanut oil solvent extraction plant

The peanut oil solvent extraction plant is one of the most important pieces of equipment in the peanut oil mill plant.Peanut oil solvent extraction plant is ideally suitable to extract and produce oil from any kind of oil cake,such as peanut / groundnut, sesame, copra, linseeds, sunflower, castor seed, cotton seed, palm kernel etc.

Peanut oil solvent extraction plant consists of extraction system,D.T.D.C system,condenser system and recovery system. Peanut oil solvent extraction plant available at small scale and big scale as per buyer's need.

Peanut oil solvent extraction plant

Peanut oil solvent extraction plant

Henan Doing Company peanut oil solvent extraction plant adopts the most scientific oil extracting method to extract crude peanut oil from peanut meal. The advanced designed production of peanut oil extraction technology provides the high capacity peanut edible oil extraction with low solvent addition.

The peanut oil solvent extraction plant is designed to extract oil directly from oil seed containing less than 20% oil like soyabean after flaking or it extracts oils from prepressed or fully pressed cake of seeds containing more than 20% oil like sunflower, peanuts, cotton seed, palm kernel, canola, copra, castor and variety of other materials.

Main equipment in peanut oil solvent extraction workshop——rotocel extractor

Main equipment in peanut oil solvent extraction workshop——rotocel extractor

Main equipment in peanut oil solvent extraction workshop——D.T.D.C system

Main equipment in peanut oil solvent extraction workshop——D.T.D.C system

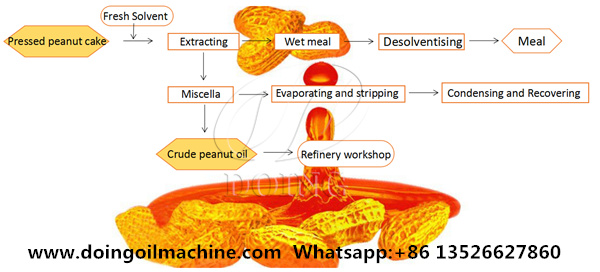

Process flow chart of peanut oil solvent extraction plant:

Peanut oil solvent extraction process flowchart

Peanut oil solvent extraction process flowchart

Functions of peanut oil solvent extraction plant main parts:

Extracting:To extract the oil in the cake by solvent, the general solvent is 6# extraction solvent oil or commercial hexane.

Desolventising:To remove and recover the solvent in the meal; Dry and cool down the meal at the same time.

Evaporating and stripping:Heating the the miscella by indirect steam, so that can vaporize the solvent and concentrate the miscella.

Solvent recycling: This process is to recover the solvent, decrease solvent comsuption,Solvent recycling can keep safety prodution and improve product quality in peanut oil solvent extraction plant.

Technical parameter of peanut oil solvent extraction plant:

| 1 | Residualoilinmeal | ≤1%(different from various oilseeds) |

| 2 | Solventconsumption | ≤1.5-3Kg/T(hexane) |

| 3 | moistureandvolatilematter | ≤0.30% |

| 4 | Powerconsumption | ≤15KWh/T |

| 5 | Steamconsumption | ≤280Kg/T(0.8MPa) |

| 6 | Finishedmealmoisture | ≤10-13%(adjustable) |

| 7 | Residualsolventinfinishedmeal | ≤300PPM(qualifieddetonatedexperiment) |

Working principle :

1) The material (for pretreatment) is sent to rotary extraction by the scraper conveyor. The material will extracted by the solvent or mix oil. After this step, we will get meal and mix oil.

(2) Meal is sent to toaster. Through the toaster, the solvent in the meal will separate from the meal. The solvent goes to condenser and is recycled to rotary extraction.

(3) After the mix oil from the rotary extraction enters into 1st evaporator and 2nd evaporator, most of the solvent in the mix oil is separated.

(4) The mix oil from 2nd evaporator goes to stripping tower and almost all the solvent is separated. From the stripping tower, we can get crude oil and solvent. The solvent is sent to condenser and is recycled to rotary extraction.

Henan Doing Company designed peanut oil solvent extraction plant has high quality and good production efficiency for peanut oil production. Its capacity is 10-600ton/d per set. So whatever production capacity you need, we can supply suitable peanut oil processing machine for you. Welcome to contact us!