Peanut/groundnut oil mill plant

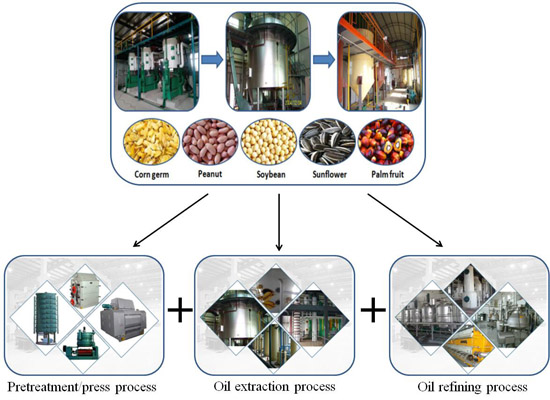

The peanut/groundnut oil mill plant we supply can be used to extract oil from various kinds of oil seeds.The peanut/groundnut oil mill plant starting with the peanut oil press workshop and endding with the peanut oil refining workshop. Next we will introduce the whole peanut oil mill plant from peanut seeds to final peanut oil.

Complete set peanut oil mill process

Complete set peanut oil mill process

Peanut seeds introduction:

Peanut,is also called groundnut.it is a kind of common oilseeds around the world. It is generally distributed in Asian, Africa, and South American,etc, especially in Brazil, China ,Egypt, Paraguay, Indonesia, Nigeria etc.

Peanut is high economic value as economic crop. It can be made some secondary product, it mainly can be extracted peanut oil. The peanut oil content is 40%-50%.

Peanut,groundnut

Peanut,groundnut

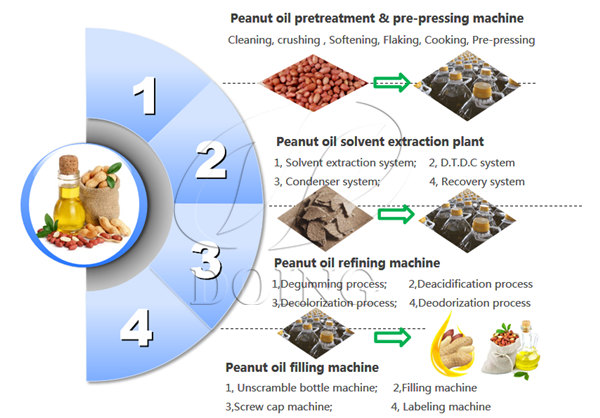

The whole peanut/groundnut oil mill plant contains three workshops: peanut oil pretreatment and pre-pressing workshop, peanut oil solvent extraction plant workshop and peanut oil refinery plant workshop.

Peanut/groundnut oil production machine

Peanut/groundnut oil production machine

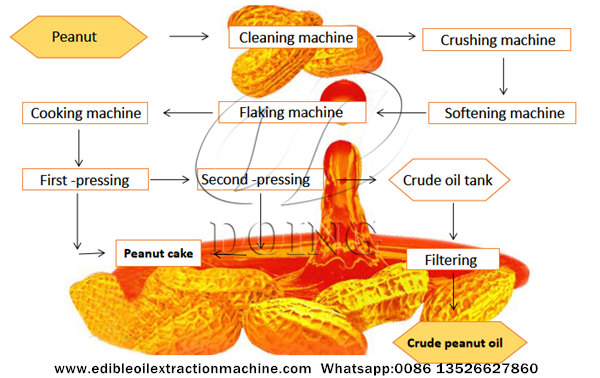

1. Craft flow for peanut oil pretreatment and prepressing workshop:

Peanut/groundnut →Husking→ Magnetic separation → Cleaning → Crusher → Flaking roll → Cooker → Oil prepressing→ Crude peanut/groundnut oil +Peanut/groundnut cake

Peanut pretreatment and pre-pressing process flowchart

Peanut pretreatment and pre-pressing process flowchart

Main Equipments of peanut oil pretreatment & pre-pressing machine:

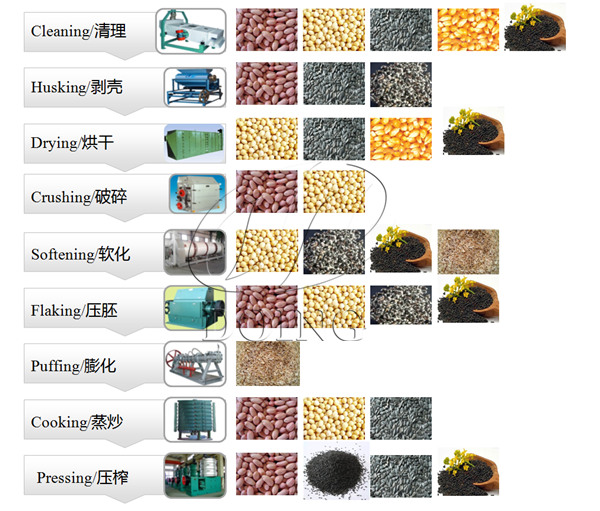

1. Husking: It is mainly for removing peanut/groundnut shell. If your raw material is peanut/groundnut seed, you do not need husking machine. If your peanut/groundnt is with shell, you need husking machine to remove shell first.

2. Magnetic box: Clearing the iron impurity which might be in the peanut. Since in the process of puffing, the iron impurity will be harmful to the screw of extrusion machine, affect the puffing effect.

3. Cleaning: This parts have different size cleaning sieves to clean the different impurities. After going through this part, most of the impurities are moved from peanut.

4. Crusher: Because of the big size of peanut, it need to be crushed to small pieces. The crusher in peanut oil mill plant will help to get more peanut oil from the seeds.

5. Cooker: This machine can adjust the water content of the peanut. It’s also good for the peanut/groundnut oil mill plant.

6. Prepressing: This peanut oil pre-pressing machine is used to take parts of the oil in the peanut first, because the high oil content in the peanut. Then the crude oil will sent to peanut oil refinery workshop, and the pressed cake will sent to peanut oil solvent extraction plant workshop.

Peanut oil pretreatment and pre-pressing machine

Peanut oil pretreatment and pre-pressing machine

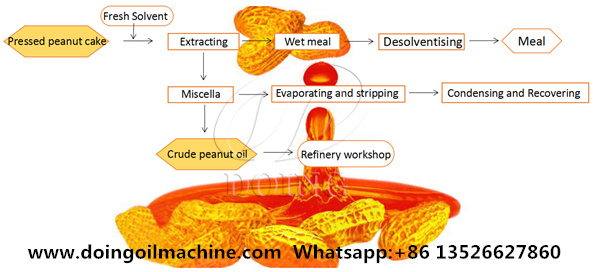

2.Craft flow for peanut solvent extraction workshop

Peanut oil solvent extraction process flowchart

Peanut oil solvent extraction process flowchart

Main Equipments of peanut oil solvent extraction plant:

1. Solvent pumps: continuously spray solvent to the rotary-typr extractor.

2. Roary extractor: spray and soak the pre-pressed cake with solvent so that oil fats can be dissolved in solvent (form miscella). After processing, you can get wet meal and miscella (mixed oil).

3. DTDC: used to separate the solvent from the wet meal.

4. Miscella tank 1st: pump the miscella ( oil with solvent) into the miscella 1st, then add 10% saline water to it. The phospholipid and impurities in the miscella will react with the saline water, at last the reactant precipitate, reaching the goal of purifying.

5. Miscella tank 2nd: the purified miscella will be pumped into it.

6. Miscella stripping: it will remove the remaining solvent in miscella. And the solvent will be discharged to condenser for recycling.

7. Condensers: used to cooling the solvent gas separated from the wet meal and miscella for recycling.

Peanut oil solvent extraction plant

Peanut oil solvent extraction plant

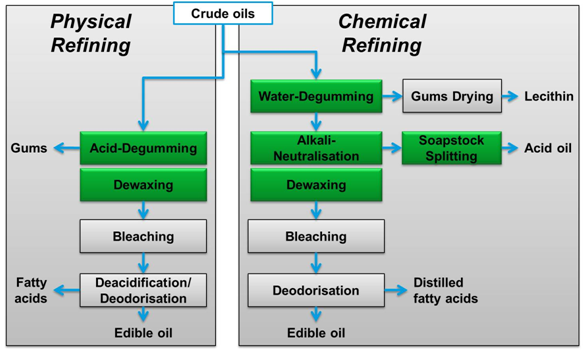

3. Craft flow for peanut oil refinery plant workshop

Generally speaking, after peanut oil pressing workshop and peanut oil ssolvent extraction plant workshop, we can get the crude edible oil. Because of it has different kinds of impurities and easy to oxidize; as a result, it cannot be stored for long time. To avoid oxidization of crude edible oil and get rid of impurities or hazardous substances, you need to set up a peanut oil refinery plant to refined crude peanut oil.

There are different capacities available for the peanut oil refinery palnt. We can provide and supply small scale as well as large scale peanut oil refinery plant. People can choose suitable peanut oil refinery plant scale to refine crude peanut oil.

Peanut oil refinery process flowchart:

Crude peanut oil → degumming and deacidification→ decolorization →deodorization → refined peanut/groundnut oil.

Chemical refining process and physical refining process of peanut oil

Chemical refining process and physical refining process of peanut oil

Main Process of peanut oil refinery plant :

1. Degumming and deacidification: The gumming is moved by phosphoric acid and hot water. There are two ways to move the acid in the peanut oil. One is chemical way, the other one is physical way. The chemical way is using NaOH to react with acid. This way is suitable for the capacity of 5-30T per day peanut/groundnut oil mill plant. The physical way is using steam and centrifugal to remove the acid. This way is used for capacity from 30-2000T per day peanut/groundnut oil mill plant.

2. Decolorization: This step is used to adjust the color of the oil. You can control the color of the peanut oil according to the requirement of your market.

3. Deodorization: The function of this step is to move the special smell in the peanut oil. This is an important standard for refined peanut oil. Because of the good smell of peanut oil, you can choose this step according to your market.

Small scale peanut oil refining machine photos

Small scale peanut oil refining machine photos

Above is the main machinery included in the peanut/groundnut oil mill plant. If you are interested in starting a peanut oil mill plant business, Henan Doing Comapny produced peanut oil processing machine is sure to surprise you! Feel free to send us an inquiry through email if you have any questions about our machines!