Why crude edible oil should be refined?

October 12, 2017 14:19/ FAQ/ leave a message

Edible oil refinery plant

Crude edible oil refers to oils that didn’t got through the oil refining process. It has many kinds of foreign matters, like sorlid residue, sand, cake residue; solloid-soluble impurities, like phospholipid, protein; oil-soluble impurities, like free fattyacid, pigment, aflatoxin, gossypol ,moisture. Due to the above impurities, the crude edible oil is easy to rancidity, which makes it in low quality and has less values in use. Therefore, it is necessary to remove these useless matters based on different using requirements and make it edible. So, the crude edible oil needs to be refined for cooking or other edible purposes.

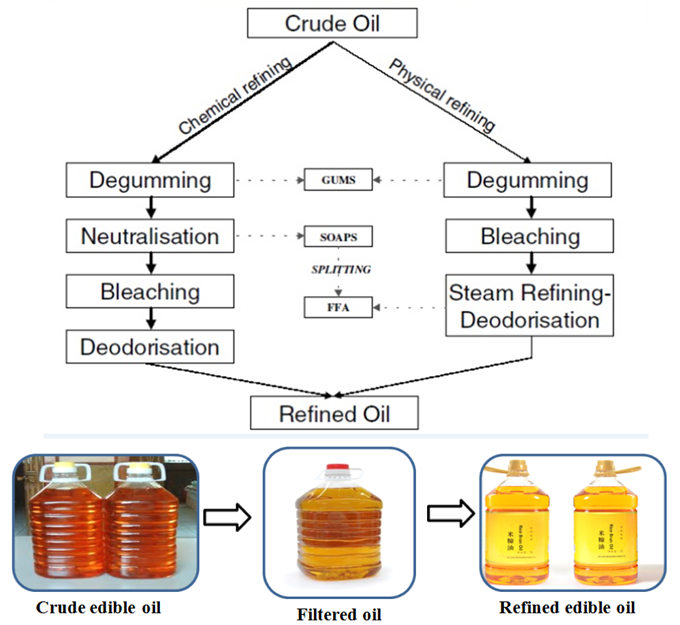

Edible oil refinery process flow chart

The typical steps in the crude edible oil refining process includes Degumming section, Neutralizing section, Decolorization/ Bleaching section, Deodorizing section.

Here, we will have a detailed introduction of our crude edible oil refinery plant. As the leading oil machinery supplier in China, we have many reputable products that of premium quality. Edible oil processing machine,edile oil press machine ,edible oil extraction machine and edible oil refinery plant have helped us build good reputation in the globe markets these years. Our crude edible oil refinery plant is suitable for small scale and large scale oil processing needs.

Batch crude edible oil refinery plant

| Capacity: | 1~30 TPD small scale crude edible oil refinery plant |

| Brief introduction: | Batch crude edible oil refinery plant contains degumming, neutralizing, decolorization and deodorization section and has all the functions of large crude edible oil refinery plant. |

| Main equipment: | heat conduction furnace, steam generator, refining pot, decolorizing pot, deodorizing pot, hot water tank, filters and other auxiliary equipment. |

| Other usage: | soybean oil, peanuts oil, sunflower oil, rapeseed oil, cottonseed oil, coconut oil, palm oil, rice bran oil, etc. |

The features of batch crude edible oil refinery plant are as follow:

Short cost recovering time and less investment

Takes up less production space and is easy to operate

Energy-saving design

Fully automatic continuous crude edible oil refinery plant

| Capacity: | 30 ~ 1000 TPD fully automatic continuous crude edible oil refinery plant |

| Brief introduction: | This fully automatic continuous crude edible oil refinery plant adopts the acid and alkali neutralization principle to remove the free fatty acid and uses disk centrifugal separator to separate the phospholipid and soap stock. |

| Main equipment: | degumming pot, neutralization tank, centrifugal separator, heat exchanger, bleaching tower, filer machine, deodorization tower, etc. |

| Other usage: | palm oil, soybean oil, cottonseed oil, canola oil, peanut oil, maize/corn germ oil, rice bran oil sunflower oil, etc. |

The features of fully automatic continuous crude edible oil refinery plant are as follow:

Has less requirements for the quality of crude edible oil

Refined edible oil has stable quality