What are the necessary machines for efficient peanut oil production?

March 19, 2025 17:37/ FAQ/ leave a messagePeanut oil, known for its flavor, nutritional value and culinary versatility, is extracted through a meticulous production process that relies on specialized peanut oil production machine. Efficient peanut oil production requires a suite of peanut oil production machine to handle all stages of the process, from cleaning the peanuts to extracting the peanut oil. In this article, we’ll explore the necessary machines for efficient peanut oil production, highlighting their functionality and importance in ensuring a high-quality end product.

1. Peanut Shelling Machine

The first step before getting peanut oil is to shell the peanuts, which is a key step in efficient peanut oil production. Take Henan Glory Company as an example, their peanut shelling machines are carefully designed to effectively separate the peanut kernels from the shells while minimizing damage to the peanut kernels. In addition, with adjustable settings, they can handle different varieties of peanuts to ensure high-quality shelling rates. Well-shelled peanut kernels are the basis for efficient peanut oil production, as damaged peanut kernels will result in reduced oil yield and poor oil quality.

Peanut shelling machine

Peanut shelling machine

2. Peanut Cleaning Machine

Before any processing, peanuts need to be thoroughly cleaned. Common peanut cleaning machines include vibrating cleaning screen, magnetic separator and stone remover. The use of these three peanut cleaning machines can remove the remaining roots, stems, leaves, soil, sand and metal impurities in peanuts. They can ensure that the peanuts entering the subsequent processing steps are clean, which is crucial to the quality of the final oil product. The use of peanut cleaning machines can not only increase the oil yield, but also improve the purity and taste of peanut oil.

Peanut cleaning machine

Peanut cleaning machine

3. Peanut Crushing Machine

Using a peanut crushing machine to crush the peanuts into small pieces increases the surface area of the peanuts, making it easier for us to press and improve the oil yield. Secondly, it can also better control the size of the peanut particles, ensuring that the peanut oil pressing process is more uniform and efficient.

Peanut crushing machine

Peanut crushing machine

4. Peanut Flaking Machine

After crushing, the next vital step is flaking. The peanut flaking process requires the use of a peanut flaking machine, which usually consists of two counter-rotating rollers or discs with an adjustable gap between them. As the peanut kernels pass through, they are flattened into thin flakes, thereby increasing the surface area of the peanuts. The larger surface area allows for better penetration of solvents (in the case of solvent extraction) or more efficient application of pressure during mechanical pressing. It also promotes better heat transfer during subsequent steaming and roasting, ensuring that the peanut material is cooked more evenly.

Peanut flaking machine

Peanut flaking machine

5. Peanut Roasting Machine

Peanut roasting machine plays a crucial role in efficient peanut oil production. Roasting gives peanut oil its unique flavor and aroma, further changes the physical and chemical properties of peanuts, improves the oil holding capacity and makes the oil easier to separate during the peanut oil pressing process. It is worth mentioning that the peanut roasting machine manufactured by Henan Glory Company can more stably control the moisture and temperature of peanuts, ensuring that the peanuts are always in the most suitable state for pressing.

Peanut roasting machine

Peanut roasting machine

6. Peanut Oil Pressing Machine

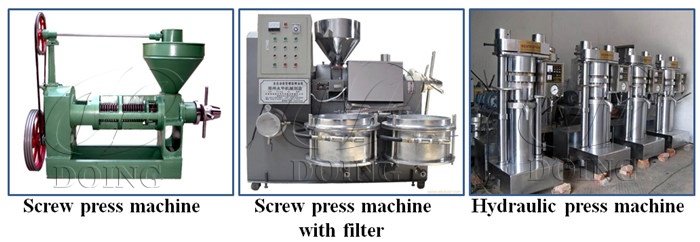

The peanut oil press machine is at the heart of efficient peanut oil production. Generally speaking, there are two types of peanut oil press machines for mechanical pressing method. One is a hydraulic peanut oil press machine, which uses high pressure to squeeze out the oil. The other is a screw peanut oil press machine, which has a rotating screw that applies pressure and pushes the flaked peanuts through a perforated barrel to separate the oil from the solid residue (peanut cake). For this, I recommend Henan Glory Oil Engineering Co., Ltd., a manufacturer specializing in the production and manufacturing of efficient peanut oil production machines, which can provide you with a series of efficient peanut oil press machines, such as hydraulic peanut oil press machines, screw peanut oil press machines, peanut oil press machine with filter and automatic temperature control integrated penaut oil press machines. These peanut oil press machines are designed with advanced pressing technology to achieve high oil extraction rates. They are made of high-quality materials to ensure durability and stable performance. Whether you are operating a small or large efficient peanut oil production line, the peanut oil press machines produced by Henan Glory can meet your production needs and maximize your profit margins.

The three kinds of peanut oil press machine

The three kinds of peanut oil press machine

7. Peanut Oil Filtering Machine

The peanut oil filtering machine is of utmost importance in efficient peanut oil production. After the peanut oil is extracted, it contains various impurities such as suspended solids, mucilage and residual meal particles. These impurities not only affect the appearance of the peanut oil, making it turbid, but also reduce its shelf life and quality. The peanut oil filtering machine can be used to remove these impurities, ensuring that the final peanut oil product is clear and bright. Common peanut oil filtering machines include plate and frame filter and leaf filter.

Peanut oil filtering machine

Peanut oil filtering machine

The above are the necessary machines for efficient peanut oil production. Each piece of peanut oil production machine plays a vital role in ensuring stable quality, maximizing yield and maintaining food safety standards. By investing in state-of-the-art peanut oil production machines and adhering to strict operating procedures, producers can provide high-quality peanut oil that meets the needs of consumers and industry. If you want to start a efficient peanut oil production business or want to invest in efficient peanut oil production machines, welcome to consult Henan Glory Company that can not only provide you with these individual peanut oil production machines, but also provide turnkey solutions for your efficient peanut oil production plant. Their team of experts will work with you to design a efficient peanut oil production line that suits your specific production scale, budget and quality requirements.