What factors will affect the final oil yield of the oil press?

November 29, 2024 15:04/ FAQ/ leave a messageThe extraction of edible oil is a complex process, so the final oil yield of the oil press involves a lot of equipment and raw materials, and each link plays an important role, including the nature of the raw materials, the operating conditions of the equipment and the pre-treatment and post-treatment methods.

Nature of Raw Materials

1、Type of Oil - Bearing Seeds or Fruits

Different oil - bearing materials have inherently different oil contents. For example, sunflower seeds usually have a relatively high oil content compared to some other common seeds. But soybean seeds don't have high oil content. The genetic makeup of these raw materials determines the maximum possible oil that can be extracted from them.

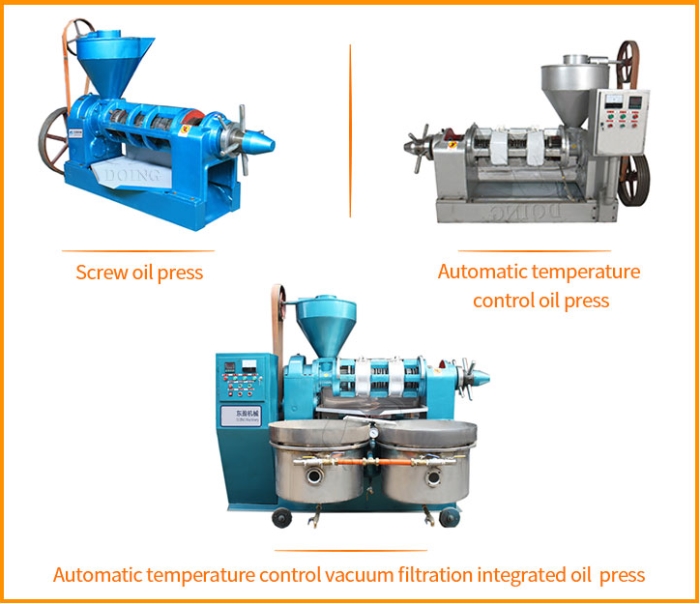

Cooking oil press machine

Cooking oil press machine

2、The quality of the raw materials

The quality of the raw materials plays a crucial role. High - quality, mature seeds or fruits generally yield more oil. Immature ones may have lower oil content as the oil - forming process within them may not be complete. Damaged or rotten materials can also reduce the oil yield. For instance, if soybeans are affected by mold or pests during storage, their oil - extracting efficiency will be negatively impacted.

Operation Conditions of the Equipment

1、Pressure and Temperature

Most oil presses operate under specific pressure and temperature ranges. Appropriate pressure is essential for squeezing the oil out effectively. If the pressure is too low, not all the oil within the raw materials will be extracted. On the other hand, excessive pressure may cause damage to the oil - containing cells and lead to the formation of impurities that can affect the quality and quantity of the oil. Temperature also has a significant impact. In some cases, a higher temperature can help in reducing the viscosity of the oil, making it easier to flow out during the pressing process. However, extremely high temperatures can cause the oil to oxidize or decompose, thereby reducing the yield.

2、Type and Design of the Oil Press

There are various types of oil presses available, such as screw presses, hydraulic presses, etc. Each type has its own advantages and limitations in terms of oil extraction efficiency. The design of the oil press, including the size and shape of the pressing chamber, the type of screw or piston used, and the overall structure, can affect how well the raw materials are processed and the oil is extracted. For example, a well - designed screw press with an optimized screw profile can ensure better contact between the raw materials and the pressing mechanism, resulting in a higher oil yield. Our company have different capacity screw oil press, if you are interested, please contact with our company.

Multifunctional fully automatic commercial use cooking oil press machine

Multifunctional fully automatic commercial use cooking oil press machine

Pre - and Post - Processing Methods

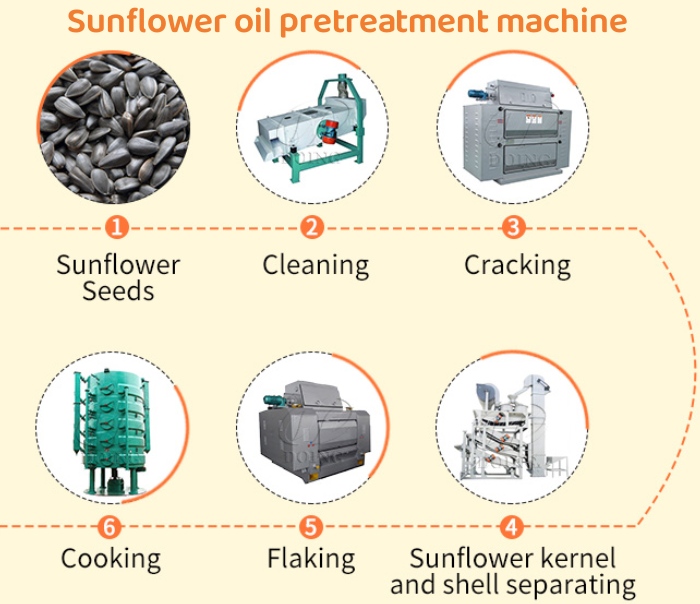

1、Pre - Treatment of Raw Materials

For sunflower seeds, soybean seeds, peanut seeds and others seeds, thepre - treatment processes like cleaning, drying, and crushing are vital. Cleaning removes any dirt, debris, or foreign substances that could interfere with the oil extraction process. Drying the raw materials to an appropriate moisture content is crucial. If the moisture content is too high, it can cause problems such as clogging the press or reducing the efficiency of oil separation. Crushing the raw materials into smaller particles increases the surface area available for oil extraction. A finer crush can expose more oil - containing cells, facilitating better oil release during pressing. For palm fruits, the sterilizer time is very important, must need to be processed in 48 hours. For palm kernel oil, if your material is palm nut, you must cracker firstly and separate.

Sunflower oil pretreatment machine

Sunflower oil pretreatment machine

2、Post - Processing of the Extracted Oil

After the oil is extracted, proper filtration and separation processes are necessary. If there is incomplete separation of the oil from other by - products or impurities, it can lead to a lower effective yield of pure oil. Additionally, storage conditions of the extracted oil can also impact its quality over time. If stored inappropriately, the oil may oxidize or deteriorate, which indirectly affects the overall success of the oil extraction process in terms of obtaining a high - quality and high - yield final product. The Henan Glory oil & Fats Engineering CO.LTD have the completely filter system include the vibrate screen, oil clarification, plate and frame filter, vacuum dryer system.

To sum up, in order to improve the efficiency of oil pressing and the quality of oil products, it is necessary to strictly control the factors such as pressure, temperature, and pre - and post - processing Methods. In thtion process, the process parameters should be flexibly adjusted according to the actual situation to achieve a better oil output effect.