What are the basic equipment needed for a groundnut oil commercial production?

April 16, 2025 16:07/ FAQ/ leave a messageGroundnut oil (also known as peanut oil) is one of the most popular vegetable oils worldwide, owing to its versatility, nutritional benefits and broad use in cooking, frying, and industrial applications. As demand for groundnut oil continues to rise, establishing a groundnut oil commercial production facility can be a lucrative investment. However, to set up a profitable and efficient groundnut oil commercial production business, choosing the right groundnut oil commercial production equipment is essential. In this article, we will explore the essential groundnut oil commercial production equipment required for groundnut oil commercial production and explain their roles in ensuring high-quality groundnut oil extraction, improved productivity and cost-efficiency.

1. Groundnut Pretreatment Equipment

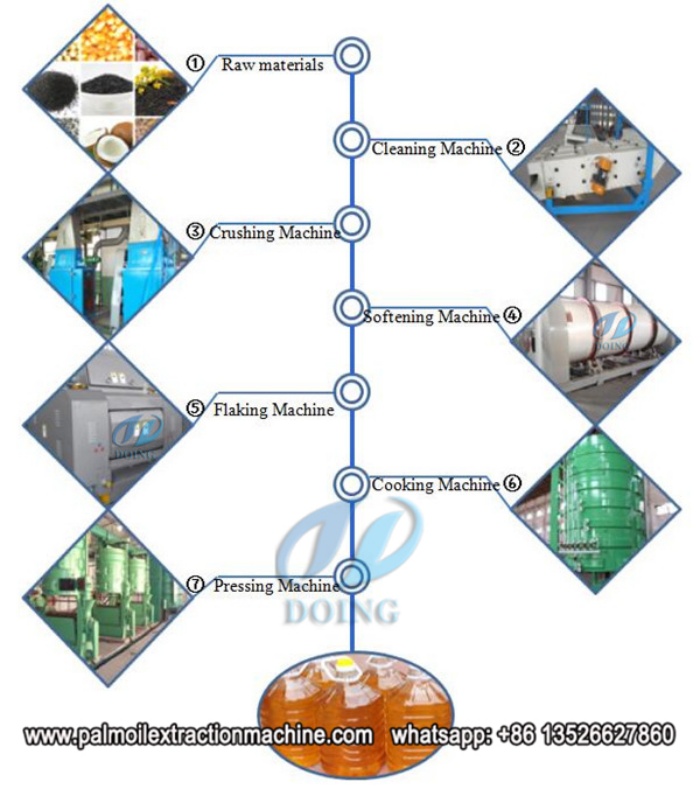

Before groundnut oil commercial production begins, the groundnuts need to be pretreated to remove impurities, dirt and foreign particles that can affect the quality of the groundnut oil, and to adjust the size and temperature of the groundnuts to meet the requirements of the groundnut oil extraction process. Proper pretreatment also ensures that the groundnut oil commercial production equipment operates efficiently without clogging. The primary groundnut pretreatment equipment equipment needed includes:

Groundnut pretreatment equipment

Groundnut pretreatment equipment

(1) Groundnut shelling equipment: Groundnut shelling equipment can not only increase the output of groundnut oil pressing equipment and improve the efficiency of oil pressing, but also reduce the wear of groundnut oil pressing equipment.

(2) Groundnut cleaning equipment: Groundnut cleaning equipment mainly includes magnetic selector, de-stonner and cleaning sieve. This groundnut cleaning equipment is used to remove metal impurities, stones, leaves and other large debris from groundnuts to ensure the purity of groundnuts.

(3) Groundnut crushing equipment: Groundnut crushing equipment can crush larger groundnuts for subsequent pressing

(4) Groundnut flaking equipment: Groundnut flaking equipment can break the cell structure of groundnuts and improve the efficiency of oil extraction.

(5) Groundnut roasting equipment: The groundnut roasting equipment can adjust the temperature and humidity of the groundnuts. The roasting process can make the groundnuts reach the best state.

2. Groundnut Oil Extraction Equipment

(1) Groundnut oil pressing equipment: Groundnut oil pressing equipment is the core of groundnut oil commercial production. It extracts oil from pre-treated groundnuts by applying high pressure and mechanical force. There are different types of groundnut oil pressing equipment on the market, but groundnut oil commercial production usually uses a screw groundnut oil pressing equipment. This type of groundnut oil pressing equipment can process a large amount of groundnuts, has a high oil yield, occupies a small area, operates efficiently and produces groundnut oil of stable quality. It is the preferred equipment for groundnut oil commercial production. If you are interested in this type of groundnut oil pressing equipment, please feel free to consult Henan Glory Company. We can provide you with screw groundnut oil pressing equipment of various models and processing capacities to meet your needs.

Groundnut oil pressing equipment

Groundnut oil pressing equipment

(2)Groundnut oil filtering equipment: To ensure that the groundnut oil does not contain any fine particles or sediment, a filter is used. The groundnut oil is passed through a filter cloth under high pressure to remove any remaining impurities. This results in a clear, pure oil that meets quality standards. The filter also improves the overall appearance and taste of the groundnut oil.

Groundnut oil filtering equipment

Groundnut oil filtering equipment

3. Groundnut Oil Refining Equipment

Once the groundnut oil has been extracted, it typically contains impurities such as free fatty acids, phospholipids and color pigments, which can reduce its quality and shelf-life. Oil refining is an essential step to remove these impurities and improve the groundnut oil’s taste, appearance and nutritional value. Key groundnut oil refining equipment includes:

Groundnut oil refining equipment

Groundnut oil refining equipment

(1) Degumming equipment: This equipment removes phospholipids, proteins and other impurities that affect the oil’s taste and clarity.

(2) Deacidification equipment: This equipment can inhibit the increase of free fatty acids in groundnut oil, which could make the oil smell rancid and impact its quality.

(3) Decolorization equipment: The equipment uses activated charcoal or clay to remove pigments from the oil, ensuring it has a clear and appealing color.

(4) Deodorization equipment: This equipment uses steam and high temperatures to remove odor-causing compounds, ensuring the oil is odorless and ready for sale.

4. Groundnut Oil Packaging and Filling Equipment

Once refined, groundnut oil needs to be packaged for sale. This process must be done with care to avoid contamination and ensure the oil remains fresh and high-quality. The essential Groundnut Oil packaging equipment includes:

(1) Filling equipment: The equipment fill the bottles, cans or bulk containers with the final product, ensuring precise measurements.

Groundnut oil filling equipment

Groundnut oil filling equipment

(2) Capping and sealing equipment: The equipment ensure the containers are sealed properly to prevent leakage and contamination.

(3) Labeling equipment: For branding and marketing purposes, oil containers need to be labeled. Labeling equipment automate this process, ensuring accuracy and efficiency.

5. Quality Control and Testing Equipment

To maintain high product standards, quality control is an ongoing process throughout groundnut oil commercial production. Testing groundnut oil commercial production equipment ensures the groundnut oil meets the desired specifications for quality, taste and safety. Key quality control equipment includes:

(1) Refractometer: Measures the refractive index of the groundnut oil, which helps to determine its purity.

(2) Moisture Meter: Ensures that the groundnut oil has a low moisture content, which is essential for long shelf-life and quality.

(3) Gas Chromatograph: Used to test the fatty acid composition of the oil, ensuring it meets health and regulatory standards.

6. Groundnut Oil Storage Equipment

Proper storage is essential to maintain the quality of groundnut oil before it reaches the market. Storage equipment must be designed to prevent contamination and oxidation, which can degrade the groundnut oil’s quality. Therefore, storage equipment is usually stainless steel storage tanks. These tanks are durable, rust and corrosion resistant, making them ideal for storing refined oils.

Groundnut oil storage equipment

Groundnut oil storage equipment

In short, starting a groundnut oil commercial production business requires investing in a variety of high-quality groundnut oil commercial production equipment to ensure that the end product meets the highest standards of quality and efficiency. If this is something you are interested in, contact Henan Glory Oils & Fats Engineering Co., Ltd. (a manufacturer that specializes in providing customers with advanced groundnut oil commercial production equipment) today to learn more about groundnut oil commercial production equipment. In addition, we can provide you with turnkey solutions for small-scale to large-scale groundnut oil commercial production. Whether you are looking to expand new business or upgrade an existing facility, our team of experts is here to help.