How is palm kernel oil made step by step?

October 31, 2024 13:49/ FAQ/ leave a messageAs we know, most customers' palm kernels are transported from their own palm oil pressing plants, or purchased from outside, then it takes a series of operations to get palm kernel oil. Below, Henan Glory company will explain to you that how is palm kernel oil made step by step .

Step 1: Removing the fiber on the palm nuts

If the fiber on the palm nut is more and long, it will influence the separating effect of palm kernel and shell. So the fist step to make palm kernel oil is to remove the fiber on the palm nuts, using fiber separating machine.

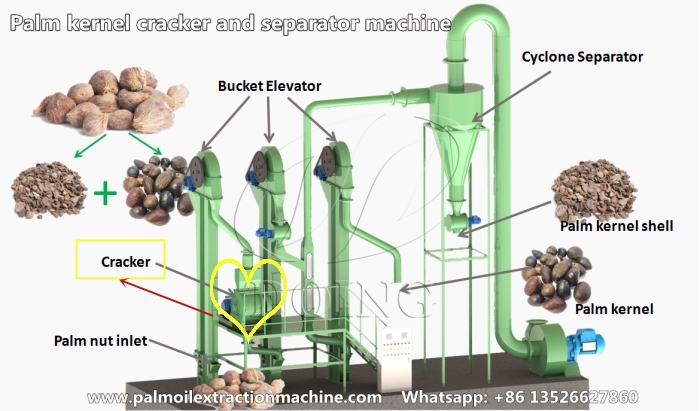

Step 2 : Separating palm kernel and shell

The clean palm kernels will then enter the magnetic separator through the bucket elevator to remove metal impurities in the palm kernels. Then they will enter the kernel grading screen to separate the palm kernels according to their size. Use the kernel-shell separation system to crack and separate the palm kernel and shell. The overall cracking and separation effect can reach about 95%.

Palm kernel cracker and separator machine

Palm kernel cracker and separator machine

Step 3&4 : Crushing palm kernel and cooking

Before entering the pressing stage, we need to crush and cook the palm kernels. Palm kernels are harder than other oils. We use a roller crusher to crush the palm kernels. The dual motor drives the gear rollers to rotate relative to each other, which has stronger power, can reduce the working pressure of the oil press and extend its life. Before pressing, the palm kernel should be cooked for conditioning the temperature and moisture to get higher quality oil and cake. The palm shells and fibers can be used as fuel, which can be recycled to reduce plant operating costs.

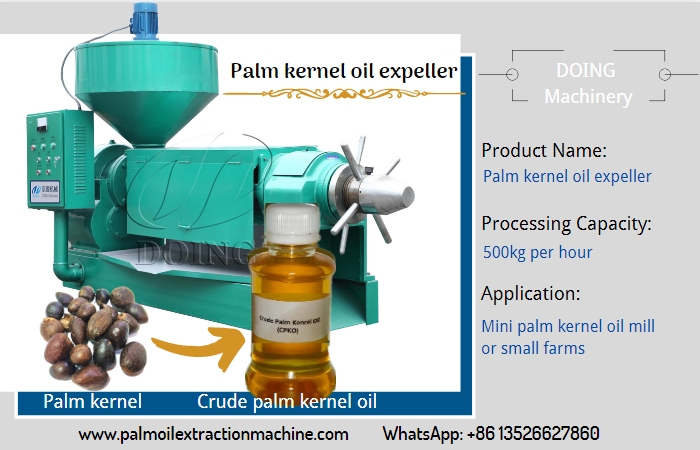

Step 5: Pressing

The round row oil press we use is a type of screw oil press, which is more wear-resistant and easy to operate and convenient when replacing accessories. The screw of the oil press adopts the short two-pole pressing process, which can well avoid the problem of sticking and blocking if the material stays in the chamber for a long time. The main material of the screw is #45 steel, which adopts the forging and dipping process to increase the hardness of the machine. The motor is equipped with a 4-level motor with sufficient power and stable operation, and the kernel oil press can ensure a residual oil rate of 6-7%.

Palm kernel oil press machine

Palm kernel oil press machine

Step 6: Filtering

Then the pressed oil goes into the plate filter through the oil pump to filter the fine impurities and remove the water, so that the oil is cleaner and can be stored for a longer time. If you want to get higher quality palm kernel oil, you also need a palm kernel oil refinery machine, which can refine crude palm kernel oil into RBD palm kernel oil.

The above shows that how is palm kernel oil made step by step. We hope that it can be helpful to you. Please feel free to leave a message on our website If you still have any questions.