What are the methods of filtering crude palm oil to get red palm oil?

April 22, 2020 14:36/ FAQ/ leave a messageCrude palm oil obtained from palm oil presser or palm oil pressing station contains many impurities, such as fibers, sands, water, which is not suitable for direct consumption or long-term storage. To get high quality and value palm oil, we usually need to use filtration machine to remove the unwanted impurities in crude palm oil. As an experienced palm oil processing machine manufacturer, supplier. Here we are glad to guide you several methods of filtering crude palm oil to get red palm oil.

1) Filter the palm oil by water boiling it;

In Africa, local people filter crude palm oil by water boiling method

In Africa, local people filter crude palm oil by water boiling method

In the very small palm oil mills of Africa, they have no modern machines, and the capacity is not big enough, they use the local traditional method to remove the impurities and water in the crude palm oil. The Africa local crude palm oil filtration method is water boiling method. Since water and oil have different boiling points, when the oil-water mixture boils, the oil floats on top. Nigerians can use bowls or other containers to extract the topmost palm oil. Then they can get the filtered palm oil.

Along with the palm oil processing industrial developing, this water boiling method can not meet the demands of the modern palm oil mills. To help more African people efficiently get clean red palm oil. We Henan Doing Company's engineers special designed the new type palm oil filter process depending on the large palm oil mill technology of Indonesia and Malaysia. Next we will introduce the second palm oil filtration method.

2) Filter the palm oil by using Doing Company designed palm oil filtration system;

This picture show the main equipment used in palm oil filtration process

This picture show the main equipment used in palm oil filtration process

Henan Doing palm oil filtration system is consists of by several parts, to help people better understanding the filtration process, next i will introduce the filtration steps one by one.

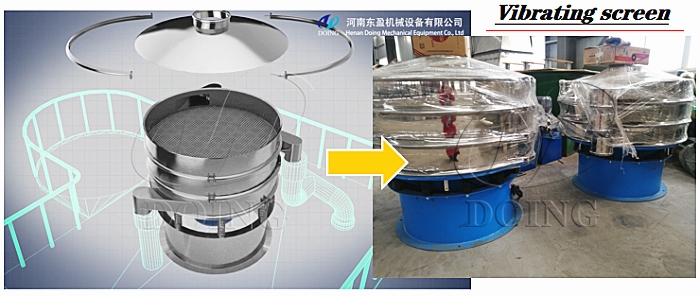

The first step is vibrating screen.

Vibrating screen used in the process of crude palm oil filtration

Vibrating screen used in the process of crude palm oil filtration

The crude palm oil will be pumped into this machine, when the vibrating screen is working, the fibers will leave on the screen, and the palm oil will pass screen and flow to the buffer tank.

The second step is clarification tank.

Clarification tank used in the process of crude palm oil filtration

Clarification tank used in the process of crude palm oil filtration

The clarification tank has the special inner structure. Which makes the clean palm oil come out from the top, and dirty palm oil drop in the bottom. Even this part can remove some impurities, but there are still some tiny impurities in the crude palm oil.

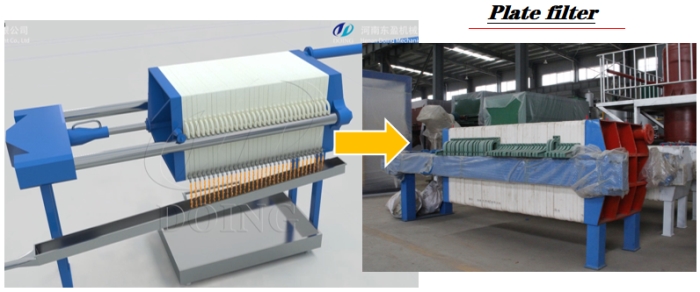

The third step is plate filter.

Plate filter used in the process of crude palm oil filtration

Plate filter used in the process of crude palm oil filtration

Plate and frame filter press is composed by the host (rack and the filter chamber), hydraulic parts and electrical parts. It used to filter the most of impurities in crude palm oil, it can ensure good filtering effect.

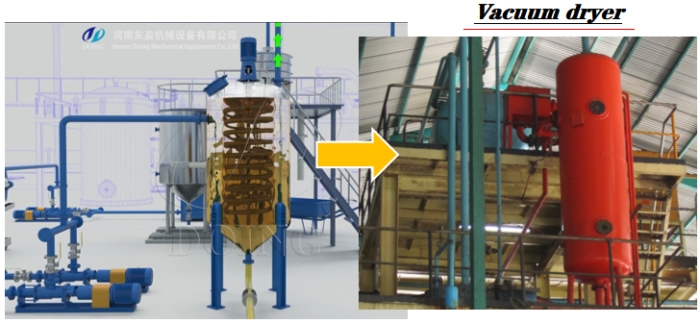

The final step is vacuum dryer.

Vacuum dryer used in the process of crude palm oil filtration

Vacuum dryer used in the process of crude palm oil filtration

The above filtration steps only can remove the solid impurities in crude palm oil, can't remove the water in palm oil. So we need to use vacuum dryer to remove the water in the palm oil. Because if the crude palm oil contains water, the water will make the CPO go rancidity, this will result in palm oil be stored a short time. To protect the palm oil no oxidation, we need to use the vacuum dryer to dry palm oil.

In general, the second filtration method can meet the production needs of most customers, but if the production scale of customers is relatively large, we can also provide to customers with Malaysia and Indonesia large scale palm oil mill filtration system.

3) Filter the palm oil by using Malaysia and Indonesia large scale palm oil mill filtration system;

Malaysia Indonesia large scale palm oil mill clarification station photo

Malaysia Indonesia large scale palm oil mill clarification station photo

In the large palm oil mills of Indonesia and Malaysia, there are five processing steps to filter crude palm oil, they are:

1) Use vibrating screen to remove the fibers;

2) Use clarification tank to settle for a period of time to remove the large impurities;

3) Next use decanter to recover the palm oil in the sludge;

4) The next step is to use plate filter to remove the small impurities;

5) Finally, we need to use vacuum dryer to remove the water in the palm oil.

After reading this article, i believe that you will know how to choose suitable palm oil filtering methods to filter crude palm oil and know the palm oil filtration steps. If you want to get one high quality palm oil filtration equipment, welcome to contact us.