Operation manual of double screw palm oil presser

April 25, 2019 14:23/ FAQ/ leave a messageDouble screw palm oil presser is an effective edible oil expeller especially designed for oil extraction with fresh palm fruits. This double screw palm oil presser has the characteristics of normal screw presses. In addition to this, it has such advantages as low breakage of palm nuts, little oil residue in pressed cake mash, no special requirement to the moisture content of raw materials, excellent workmanship, compact structure, large capacity, stable and reliable operation, little maintenance work needed and its rigidity and durability etc. At present double screw palm oil presser is very popular in many palm oil production countries for its successful performance.

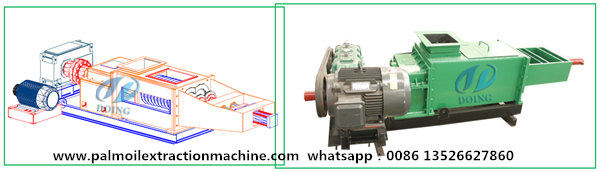

The leaf Fig is model of double screw palm oil presser machine, the right Fig is 1tph double screw palm oil presser machine

The leaf Fig is model of double screw palm oil presser machine, the right Fig is 1tph double screw palm oil presser machine

Working Principle of the double screw palm oil presser:

The mechanical working principle of this double screw palm oil presser lies in that the volume of flakes in the barrel becomes smaller and smaller due to the expelling action from the rotation of the screw shafts and the resistance from a cake thickness adjusting mechanism. In the combined action of these devices, most palm oil can be extract out.

1tph doubel screw palm oil presser machine

1tph doubel screw palm oil presser machine

How to operate the double screw palm oil presser scientifically? Please continue reading, you will find answer.

Operation before Start-up

Either operating new double screw palm oil press machine or resuming operation after maintenance, checking must be done before start-up. The checking work mainly includes the following points:

1.1 Clear away the material and impurities left inside the inlet and barrel, and close the outlet of the digester so as to prevent the accumulated material from entering the barrel and getting the barrel blocked.

1.2 Check over every part of the driving system (including the reducer and the oil level in the gearbox), the alignment and tensioning of the belts, ensuring that there is not any hitch existing.

1.3 Check that every connection is all right and secure.

1.4 Check that the oil circuit in the hydraulic system is unblocked and free of leakage, and that every reversing valve and throttle valve etc can work normally. All the pressure gauges must be checked and calibrated.

1.5 Check the electrical system, tighten all the connection terminals and ensure that resistance does not exceed 5Ω.

1.6 Check the three phase current and voltage, and set the overload current as the maximum amperage of the motor.

1.7 Turn the big V-belt pulley with hands to check that it rotates freely without any click and other abnormal noise.

1.8 Start the motor first, examine if it rotates in right direction. Then let it run idly for a certain while, and examine its running conditions again. In case of that it is under a relatively higher load, the cause may be that the driving belts are excessively tightened, or the gears are poorly engaged, or too much lubricating oil has been filled, or there is some trouble in the motor. So checking must be done item by item, and the machine must not be put into production until it runs idly in a normal way.

2. Start-up Operation

2.1 Feed the digester (clasher) to a medium level of the tank.

2.2 When the temperature has been kept for 15 ~ 20 minutes, start the motor of the double screw palm oil presser to let machine run idly for 2 ~ 5 minutes.

2.3 Open the discharge gate of the digester to feed the double screw palm oil presser. (Note: The feeding rate should be increased gradually.)

2.4 Once the outlet has cake comes out, before starts the hydraulic motor, you must ensure the manually hand valve is in the middle position. Then starts the hydraulic system, the adjust cake cone moves to cake outlet direction, and increase pressure gradully, adjust to best situation(according to fiber cake oil residue situation).

2.5 With the feeding rate increases gradually, the pressure inside the barrel increases. At this time, the pressure inside the hydraulic system should be adjusted so as to increase the pressure inside oil cylinder to 50 ~ 70 B (5 ~7 MPa).

3. Operation under Normal Running Conditions

3.1 Keep the load stable

Normal production can be realized only when there is enough pressure inside the barrel, and whether the pressure is normal or not is mainly indicated in that the load in stable or not. In order to make the load stable, the following points should ensured: (1) There should be no high fluctuation in the ammeter reading; (2) The reading on the manometer in the hydraulic system should be kept within the range of 50 ~ 70 B (5 ~ 7 Mpa).

3.2 Keep the feeding uniform

Un-uniform feeding will result in fluctuating pressure, which will impact oil extraction. Sometimes it will cause the pressure inside barrel to exceed 70 B (7 Mpa), resulting in motor burning and failures in the hydraulic system etc. Therefore, operators must frequently inspect the outlet of the digester to prevent the tank from running out of material, and to always keep the feeding uniform.

3.3. Keep an eye on the cake discharging conditions.

More information about operation manual of double screw palm oil presser, please send inquiry to palmoil@doingmachinery.com.