How many tons of the palm kernels will produce 1 ton of the palm kernel oil (PKO)?

April 25, 2025 14:15/ FAQ/ leave a messageAt Henan Glory Oils & Fats Engineering Co., Ltd., we are committed to providing our clients with high-quality, reliable palm kernel oil production machines. One of the most frequently asked questions by our customers is how many tons of the palm kernels will produce 1 ton of the palm kernel oil (PKO). To answer this question, you need to understand the relationship between palm kernels and the production of palm kernel oil (PKO), as well as the variables that can affect the yield.

1. Understanding Palm Kernel Oil (PKO) Production

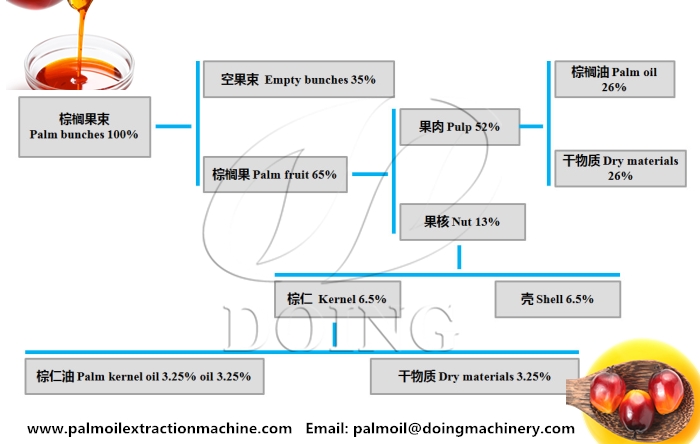

Palm kernel oil is extracted from the seeds of the oil palm tree, also known as the palm kernel. The oil palm tree produces fruit clusters that contain both palm oil (from the flesh of the fruit) and palm kernel oil (from the seeds). The palm kernel oil (PKO) production is a multi-step process, starting with the collection of palm fruits, followed by the separation of the nuts from the flesh, and finally, the mechanical or chemical extraction of oil from the kernels.

Palm kernel oil (PKO) production

Palm kernel oil (PKO) production

2. Identifying Factors Affecting the Yield of Palm Kernel Oil (PKO)

The yield of Palm Kernel Oil (PKO) from palm nuts depends on several factors, including:

(1) Quality of the Palm Kernels: The quality of the palm kernels plays a significant role in determining the palm kernel oil (PKO) yield. High-quality palm kernels, which are properly harvested and processed, tend to produce a higher palm kernel oil (PKO) yield.

(2) Oil Content and Residual Oil Rate: The oil content of palm kernel itself and the residual oil rate caused by palm kernel oil production equipment will also affect the yield. Generally speaking, the oil content of palm kernel is 50%-55%. Taking the extraction of palm kernel oil by Henan Glory Company's high-quality palm kernel oil production equipment as an example, the residual oil rate can be reduced to 7%.

Oil content of palm kernels

Oil content of palm kernels

(3) Moisture Content: The moisture content of the palm kernels also affects the efficiency of palm kernel oil production. Palm kernels that are too dry or too wet may result in lower oil extraction rates.

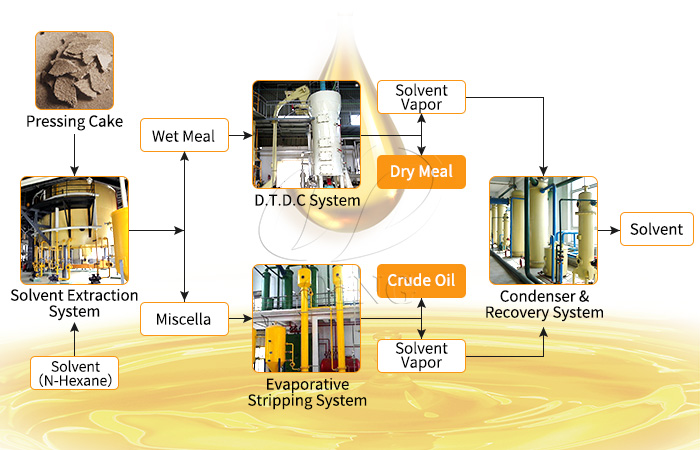

(4) Production Technology and Efficiency: The traditional mechanical pressing method is used to produce palm kernel oil, and the residual oil rate is generally high. The chemical solvent n-hexane is used to produce palm kernel oil, and the residual oil rate is relatively low, but the investment cost is high. It is worth mentioning that the palm kernel oil solvent extraction equipment of Henan Glory can reduce the residual oil rate of palm kernel oil production to 1%, so as to achieve the maximum extraction of palm kernel oil.

Palm kernel oil solvent extraction equipment of Henan Glory

Palm kernel oil solvent extraction equipment of Henan Glory

3. Average Yield of Palm Kernel Oil

On average, it takes approximately 2.1-2.4 tons of palm kernels to produce 1 ton of the palm kernel oil (PKO). This conversion ratio can vary depending on the factors mentioned above. For example, using high-quality palm kernels and advanced palm kernel production technology can result in a more efficient process, yielding more oil per ton of kernels.

In summary, how many tons of the palm kernels can produce 1 ton of the palm kernel oil (PKO) will vary depending on factors such as extraction method, palm kernels quality, etc. As a leading supplier and exporter of palm kernel oil production equipment, Henan Glory Oils & Fats Engineering Co., Ltd. will support your business with reliable and high-quality palm kernel oil production equipment. If you are interested in ordering or learning more information, please feel free to contact us for a personalized quote.