How does peanut oil refining machine work? What is the refining process of peanut oil?

June 4, 2021 10:53/ FAQ/ leave a messageThe pressed peanut oil and the extracted peanut oil contain impurities, free fatty acids, waxes, unpleasant smell, pigments, a small amount of water, etc., which are harmful to human health and storage and affect the quality of peanut oil. Therefore, the peanut oil refining machine is very important. Someone may ask how does the peanut oil refining machine work? What is the refining process of peanut oil? Let's discuss it in detail.

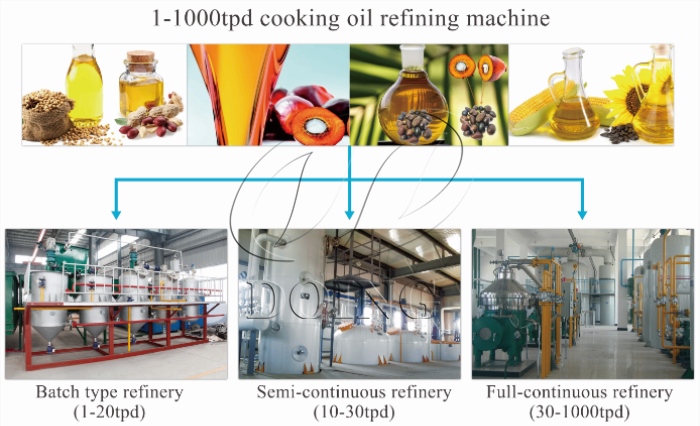

Batch type, semi-continuous type and fully continuous soybean oil refining machine

Batch type, semi-continuous type and fully continuous soybean oil refining machine

Refining principle of peanut oil refining machine:

Peanut oil refining machine is mainly through hydration degumming, alkalization deacidification, clay adsorption decolorization, high temperature deodorization and other process to remove the impurities in crude peanut oil to get high quality cooking oil.

Recommeded reading: 1-10tpd batch type peanut oil refining machine

Refining process of peanut oil:

(1)Degumming:

Peanut oil is mostly degummed by hydration, that is, hot water or electrolyte solutions such as dilute alkali, salt and phosphoric acid are added into peanut oil by using the hydrophilicity of colloidal impurities such as phospholipids to make the colloidal impurities absorb water and condense, and then settle and separate from the oil.

(2) Deacidification:

Chemical deacidification is often used, that is, adding alkali liquor into peanut oil to neutralize with free fatty acids, so as to achieve the effect of deacidification. Deacidification is carried out in deacidification tower.

(3) Decolorizition:

Generally, adsorption decolorization is a better choice for peanut crude oil. Adsorption decolorization is a process in which pigment and other impurities in peanut oil are adsorbed by clay with strong adsorption. After decolorization, the waste clay in crude oil needs to be filtered by a blade filter. The process of decolorization and filtration should be repeated 2-3 times to ensure good decolorization effect.

(4) Deodorization:

Deodorization is a process of deodorization in crude oil by introducing direct steam under high temperature and high vacuum conditions. This process uses a deodorizer. Due to the high reaction temperature, the deodorization tower is mostly made of stainless steel.

After refining, you can get high quality peanut oil which meets the national standard and is edible. You can pump it into a tank, fill it and sell it.

Soybean oil refinery plant project

Soybean oil refinery plant project

Henan Glory Oils & Fats Engineering Co., Ltd is a comprehensive cooking oil refining machine manufacturing enterprise, integrating process design, technology research and development, manufacturing, sales and after-sales service. We can supply three types peanut oil refining machine for people to choose, they are: 1-20tpd batch type peanut oil refining machine, 20-50tpd semi- continuous peanut oil refining machine and 50-600tpd fully continuous peanut oil refining machine. No matter what kind of refining equipment you need, we can provide you with the suitable equipment.