What is the difference between physical refining and chemical refining of edible oil?

December 5, 2019 14:45/ FAQ/ leave a messageEdible oil refining is a relatively complex and flexible process. On the whole, edible oil refining methods can be divided into physical refining method and chemical refining method. Many customers don't know their difference clearly. Now, I will simplely expain it.

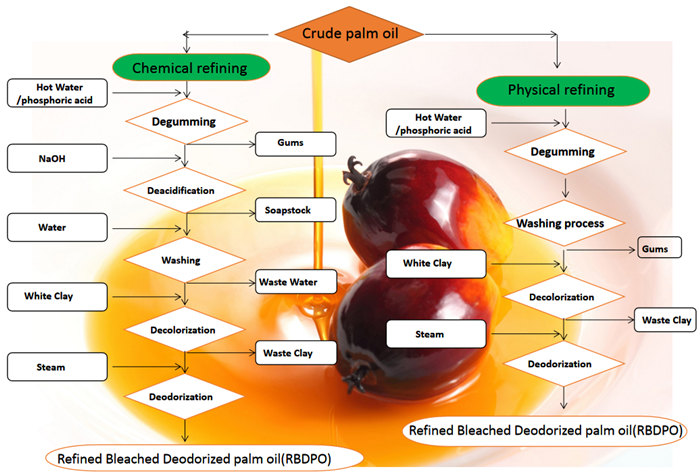

Physical refining and chemical refining processes flowchart:

Physical refining and chemical refining process of edible oil

Physical refining and chemical refining process of edible oil

What is physical refining of edible oil?

Physical refining is also known as steam refining. In degumming process, it utilizes citric acid or food grade phosphoric acid to remove natural gums in the form of phosphatides. Then, in bleaching process, under vacuum, activated clay is used to remove colouring matters and adsorb any metal ions. The deacidification and deodorization process is under high temperature and low pressure. By using steam, the FFA can be removed. What's more, the off-flavors and odours can also be removed from the crude edible oil in the steam distillation process.

100tpd palm oil physical refining project case in Kenya

100tpd palm oil physical refining project case in Kenya

What is the features of edible oil physical refining?

(1) The consumption of auxiliary materials is small, which reduces the pollution of wastewater to the environment. Deacidification by distillation can directly obtain fatty acids. No alkali is used, no soap is formed, and the oil does not have to be washed. It is no longer necessary to use acid to deacidify the soap to prepare fatty acids. Sewage due to acid-base treatment is avoided.

(2) The physical refining process is simple and the equipment is small. The deacidification and deodorization are combined into one process in the same equipment; the oil is not washed with water; the soap foot treatment section is omitted, thereby simplifying the physical refining process and reducing the equipment cost.

(3) High edible oil refining rate. There is no neutral oil saponification loss and emulsification loss. The higher the acid value, the more obvious this advantage. By physical refining process, edible oil loss can be reduced to below 1.05% to 1.1%.

(4) The product quality is good. The product oil has good stability, and the fatty acid (containing 85% to 90% free fatty acid) directly obtained during distillation is superior to the fatty acid obtained by acid hydrolysis and distillation after alkali refining.

What is Chemical refining of edible oil?

Chemical refining means chemically removing FFA (acid-base neutralization). In refining process, it utilizes alkali liquor to neutralize the acid in crude oil. But after edible oil degumming and deacidification process, the soap will be produced, usually, we need to use washing method or centrifugal separation method to process soap. Then, in bleaching process, under vacuum, activated clay is used to remove colouring matters and adsorb any metal ions. Same purpose as physical refining of edible oil, the deodorization section mainly used to remove off-flavors and odours in crude edible oil by the help of steam distillation.

20tpd palm oil chemical refining project case in Peru

20tpd palm oil chemical refining project case in Peru

What is the features of edible oil chemical refining?

(1)The chemical refining is the traditional edible oil refining methods, the chemical refining adaptability is strong, the requirements for raw oil is not high. That is to say, it can be used to refine most crude edible oil, such as soybean oil, peanut oil, sunflower oil, cottonseed oil, rapeseed oil, rice bran oil, mustard oil, palm oil, palm kernel oil and so on.

(2) Although the consumption of auxiliary materials is large, the soap can be produced during edible oil refining process. It can be used as the raw materials of soap making machine. Overall, the by-products of edible oil chemical refining can increase the economic value of refining machine.[You may interested in: What types of edible oil can be refined by edible oil refinery plant?]

(3) Compared with the physical refining, the consumed amount of activated clay is less.

Physical refining and chemical refining have their own characteristics. However, in edible oil refining process, it doesn't mean you have to use physical refining or chemical refining method. Sometimes, physical refining method and chemical refining method will be used simultaneously according to the quality of the crude oil.

As for which refining technology is better, it depends on your requirement. You can tell us your specifications of crude oil, and the requirement of final edible oil, and our engineers will design the most suitable proposal for you, to help you build a best quality and cost-effective edible oil refinery plant.[You may interested in: How to choose suitable edible oil refining process?]

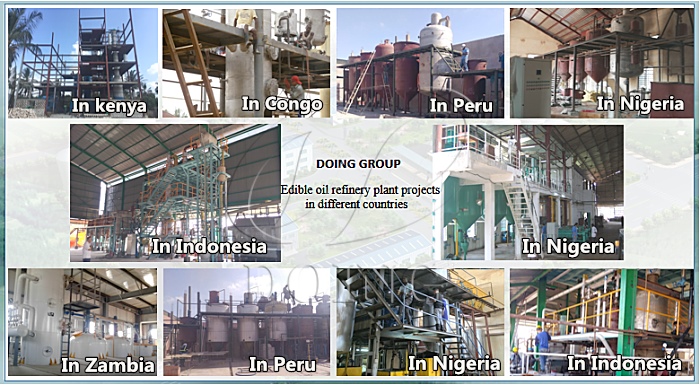

Henan Doing Company has engaged in edible oil refinery plant filed many years, and built many projects in Mexico, Peru, Indonesia, Malaysia, Kenya, Nigeria, and so on.[You may interested in:How much it will cost to set up an edible oil refinery plant?]

Edible oil refinery plant projects were built by Henan Doing Machinery

Edible oil refinery plant projects were built by Henan Doing Machinery

About the edible oil refinery plant, Henan Doing Company can do the input capacity from 1ton/day to 1000tons/day. For the different capacity, the refining technology are different. If you'd like to get more information about edible oil refining machines and edible oil refining process, please don't hesitate to contact us. We are always at your service.