Sunflower oil refining technology and sunflower oil refining process

October 15, 2018 09:34/ FAQ/ leave a messageOver the past decade, Henan Doing Machinery has supplied more than 20 edible oil refinery plants for customers, dealing with oil from soybean, corn germ, rapeseed, peanut, rice bran and other oil seeds. Henan Doing Machinery always insist on science and technology are the primary productive forces, during edible oil refining machine manufacturing process, Henan Doing Machinery optimized some production equipment and edible oil refining process technology.

With the development of sunflower oil refining technology, Henan Doing Machinery has designed and developed a new type of sunflower oil refining process technology. At the same time, the whole production line is equipped with complete automatic control system. Because of the application of above sunflower oil refining technologies, production electricity consumption, steam consumption and fuel consumption have been reduced.

Generally, Crude Sunflower oil mainly contains hydratable & non-hydratable gums, free fatty acids, coloring pigments like Carotenoids, moisture, oxidative component like aldehyde & ketone, metallic element, waxes and other impurities which is bad for our health.So there are many steps needed before we get that golden palm oil you see at the supermarket.

Sunflower oil refinery plant

Sunflower oil refinery plant

Sunflower oil refining consists of the following sections:

Degumming

Neutralisation

Bleaching

Dewaxing

Deodorisation / De-acidification

Generally, there are two refining methods of sunflower oil: Physical refining and chemical refining. However, it doesn’t matter what kind of refining method to be used, they all are done with the help of various equipments & machinery inside the refinery and all the oils extracted from oil seeds like Sunflower, Cottonseed, Peanuts, Sesame, Soybean etc. Follows are the sunflower oil refining process:

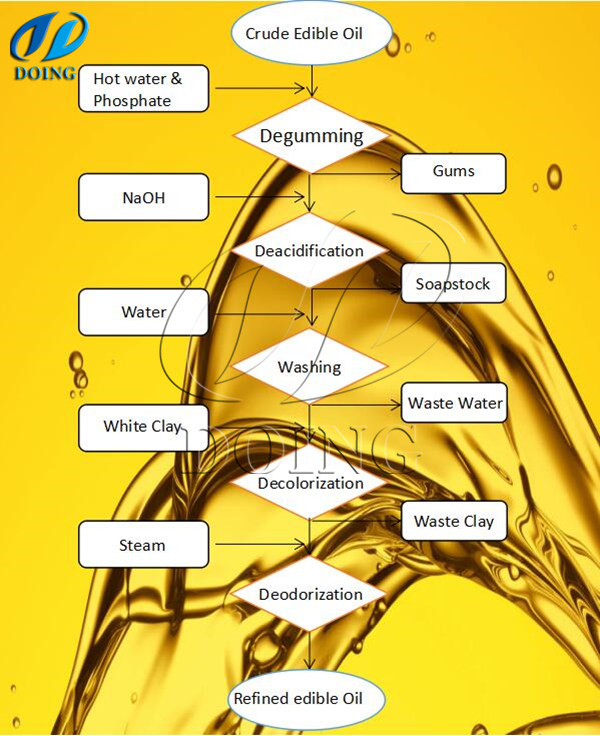

Sunflower Oil Refining Process flow chart:

Sunflower oil refining process flow chart

Sunflower oil refining process flow chart

Main process of sunflower oil refining:

The first step in refining involves the degumming of the Crude Sunflower Oil. Degumming is done for the treatment of the Phosphatides & other impurities. Technically, Degumming is the purification of the sunflower oil which normally contains impurities in colloidal state& dissolve in them.

While doing degumming of crude sunflower oil process, we remove hydratable and non hydratable gums by using Salt water, dilute acid such as phosphoric acid / Citric acid / oxalic acid / tartaric acid.

The hydratable gums are insoluble in oil and can remove using water by centrifugation method. The non hydratable gums are soluble in oil and can remove using acid by making them hydratable or insoluble in oil.

Non – Hydratable gums are Phosphatidylethanolamine and magnesium & calcium salt of Phosphatidic acid.

Henan Doing Machinery follows different type of degumming processes like Water Degumming/Acid Degumming/ Enzymatic Degumming. These processes are being selected based on methods of processing, chemicals used and the content of phosphatides in the crude vegetable oil.

Neutralization section of sunflower oil refining process:

Neutralization of degummed oil involves the reaction between free fatty acid and alkali solution such as sodium hydroxide /Potassium hydroxide. The result is formation of Sodium soap takes place and settled in the neutralizer machine and removed as a soap stock.

Bleaching Section of Sunflower Oil Refining Process:

The bleaching of Sunflower oil is an essential part of the sunflower oil refining process after degumming / Neutralization. Originally the bleaching was only used to remove the color. Now a days bleaching process are used to remove coloring pigments as well as some undesirable impurities which are harmful to human consumption.

The Bleaching step is normally carried out after alkaline refining / Neutralization or Degumming. In this process we mainly remove the coloring pigments like carotenoids & chlorophyll, some oxidative products, soap traces, metals and residual phosphatides. All these compounds have adverse effect on quality and shelf life of oil, and therefore be needed to remove to make the product commercially attractive and long shelf life.

Dewaxing Section of Sunflower Oil Refining Process:

Dewaxing of the Sunflower is required in order to reduce the cloud point of the refined sunflower oil. The small quantities of solids from oil are removed that would normally cause cloudiness of the oil. These substances can be saturated glycerides or waxes. Waxes are esters for fatty alcohol and fatty acid, which have a very low solubility in oil. There quantity is different in different oils.

Generally, varies in between 48-2000 ppm.

In order to obtain oil with good cold stability, the wax content needs to minimize with respect to the atmospheric temperature. In this process cooling rate & agitation are carefully controlled to promote the formation of nuclei that will serve as the sites for crystal growth.

In Winter season when the temperature is low, waxes appears in the oil causes haziness.Winterization or dewaxing of Sunflower is necessary to produce salad oil.

Deodorization Section of Sunflower Oil Refining Process:

The Deodorization or deacidification is actually stripping process in which a little amount of low pressure steam passes through hot oil. In Sunflower Oil Deodorization process various types of volatile molecule and odoriferous compound removed. This process carried out at very high temperature more than 200 degrees Celsius.

In Deodorisation process we also do thermal destruction of flavor and heat sensitive coloring pigments. A little amount of Coloring pigments is removed. Time play important role in this process, deodorization is the high temperature and high vacuum steam distillation process. It is used to remove high volatile and odoriferous material present in bleached oil.

If the Deodorization time is too short than some odoriferous compounds will remain in deodorized oil and resulting is the development of flavor again during storage of oil. if the Deodorization time is too long than oil can be polymerized due to high temperature and high vacuum.

Henan Doing Machinery is a well-known manufacturer of full-line sunflower oil processing plant, sunflower oil refining plant & oil mill machines. If you are interested in setting up an vegetable oil processing plant, refining plant, please let us know and we shall be pleased to send you the list of most suitable equipments with quotations once receive your inquiries. Just feel free to contact us!

Note:

Sunflower oil is widely used in world vegetable oil market

Sunflower oil is widely used in world vegetable oil market

Sunflower oil is very important edible oil all the way. Sunflower seeds are produced in many countries including Ukraine, Russia, China, Bulgaria, Romania, United republic of Tanzania, Turkey, Hungry, France, and Argentina etc.

Sunflower oil is widely used as cooking oil which is extracted by solvent extraction method or screw oil press method from sunflower seed.