What is the best edible oil production process?

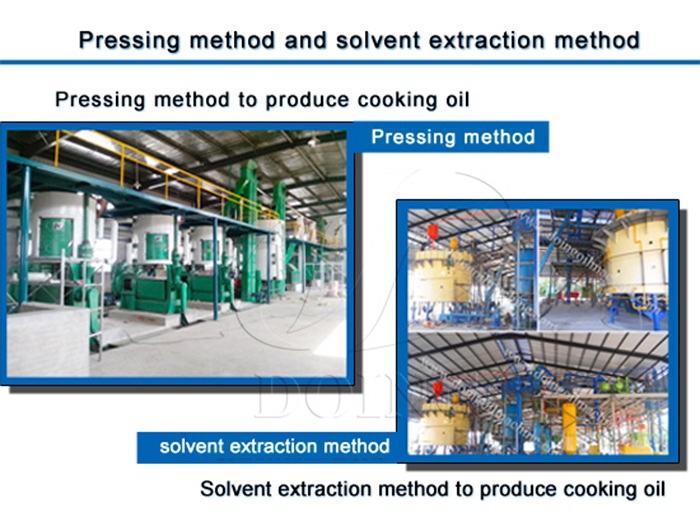

August 31, 2023 11:33/ FAQ/ leave a messageThere are two edible oil production processes, edible oil production process using pressing method and edible oil production process using solvent extraction method. Most small and medium-sized manufacturers use the pressing process, while large-scale manufacturers can opt for solvent extraction. The best edible oil production process is the one that meets the customers' requirements. As each customer's circumstances are different, their desired edible oil production processes and equipment may also vary. Only a personalized process that aligns with the customers' needs can be considered the best. To achieve this objective, we provide professional customized services to ensure optimal adaptability and quality.

The best edible oil production process photo

The best edible oil production process photo

Edible oil production process using pressing method

For the processing and production of edible oil, most manufacturers use a edible oil production process using pressing method. Firstly, because the production of edible oil is not as large-scale as the production of popular oils, and it is a niche. Most of the investment in edible oil production lines is in small and medium-sized edible oil processing enterprises. A complete edible oil production line requires vibrating screen, de-stoner, magnetic separator, flaking machine and other equipment. There are many models of edible oil pressing production lines, which can be customized according to production, budget and other needs, saving equipment investment. Secondly, the edible oil production process using pressing method uses the principle of physical extrusion to squeeze oil out of fat, which fully preserves the nutritional taste of edible oil and it is becoming more popular with consumers.

Edible oil production process using pressing machine photo

Edible oil production process using pressing machine photo

Edible oil production process using solvent extraction method

Large scale edible oil processing plants can use the edible oil production process using solvent extraction method to produce edible oil. The edible oil production process using solvent extraction method uses the principle of solvent extraction to ensure full contact between the oil and the solvent in the extraction device, extract the oil, and then remove the solvent by evaporation to obtain leached edible oil. Solvent extraction generally consists of four systems: solvent extraction system, wet meal DTDC system, mixed oil treatment system, and solvent recovery system.

The edible oil production process using solvent extraction method has the advantages of high automation, large processing power, high oil yield and low labor intensity. It is an internationally recognized advanced technology for processing grease. After edible oil solvent extraction, the oil content in the meal is less than 1%, so that more edible oil can be obtained and edible oil loss can be reduced. However, the quality of crude oil is not as good as that of pressed crude oil. It must be refined using edible oil refining equipment to remove impurities and solvent residues before it can be eaten.

Edible oil production process using solvent extraction machine photo

Edible oil production process using solvent extraction machine photo

The edible oil production process using solvent extraction method can be divided into two types: direct solvent extraction and pre-pressed solvent extraction. Oils with a high oil content, such as sunflower, flaxseed, can be obtained by pre-pressed solvent extraction, which can not only produce pressed crude oil with better nutritional and flavor retention, but also improve oil yield and improve efficiency.

The edible oil production process is currently very developed. If you need edible oil production equipment, you must consider the quality, safety and technology of edible oil production equipment. Henan Glory Company has been established for 12 years and has a professional technical team and our own processing factory, which can provide professional customized services. The specific needs are to configure customized solutions that can meet the needs of each customer based on their actual situation. If you have any needs, please feel free to contact us.