What is the function of soybean cleaning before pressing?

November 9, 2021 15:33/ FAQ/ leave a messageSoybean cleaning is an important step of soybean oil production process. Before pressing soybean, only by ensuring that the soybean raw materials are cleaned, can the subsequent soybean oil production process proceed smoothly and the obtain soybean oil quality be guaranteed.

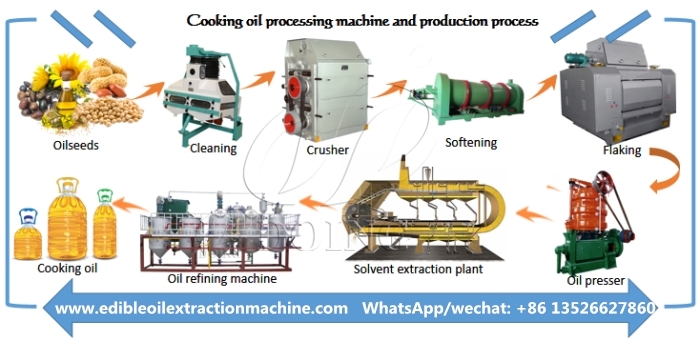

Soybean oil production process

Soybean oil production process

The detailed functions of soybean cleaning before pressing are as follows:

◆ Conducive to storage and transportation: organic impurities are moldy, occupying warehouse volume, blocking equipment, and polluting the environment

◆ Reduce oil loss: increase oil yield

◆ Improve the quality of fats and oil cakes

◆ Increase equipment production capacity and reduce equipment wear

◆ Avoid production accidents and prevent environmental pollution

◆ Improve the effect of processing technology

Soybean cleaning equipment

Soybean cleaning equipment

1. Vibrating screen: used in the cleaning process to separate big and small impurity, like weed, etc.

2. Suction type gravity stoner: it can remove shoulder stone, earth and other heavy impurities.

3. Magnetic separator: it is carried out by using the difference in mechanical strength of soybeans and impurities, it can remove magnets, iron and so on without power and exhaust system, and with dust removing wind net is installed.

If you are interested in our soybean cleaning equipment or the whole set soybean oil processing equipment, please contact Henan Glory Oils & Fats Engineering Co., Ltd and tell us your requirements, we have the professional engineers team to customize the most suitable equipment and offer you the best service for you!