Niger client successfully purchased 10TPD palm oil processing machine from Henan Glory Company

April 5, 2023 13:52/ DOING News/ leave a messageOn April 4, 2023, a client from Niger purchased two sets of 10TPD palm oil processing machine from Henan Glory Company. Below is a picture of the 10TPD palm oil processing machines:

10TPD palm oil processing machine from Henan Glory Company

10TPD palm oil processing machine from Henan Glory Company

The client is a CEO of one shipping company , now they want expand their business and do some Shift to Manufacturing development, first they want to do some business about palm oil processing machine, after consult our palm oil processing machine, He believed in our equipment and technology, and decided to start with 10TPD palm oil processing machine.

He places great important on the quality of the equipment and he also hopes to purchase suitable machine as a more favorable price. After multiple comparisons, the client was very impressed with the following aspect of our equipment, and ultimately chose us.

One is the designprocess of machine:

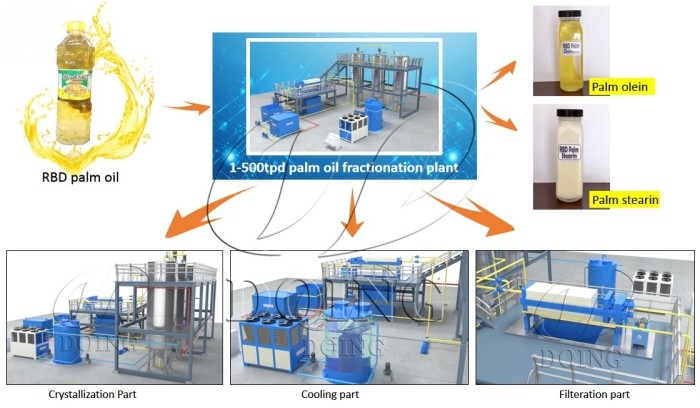

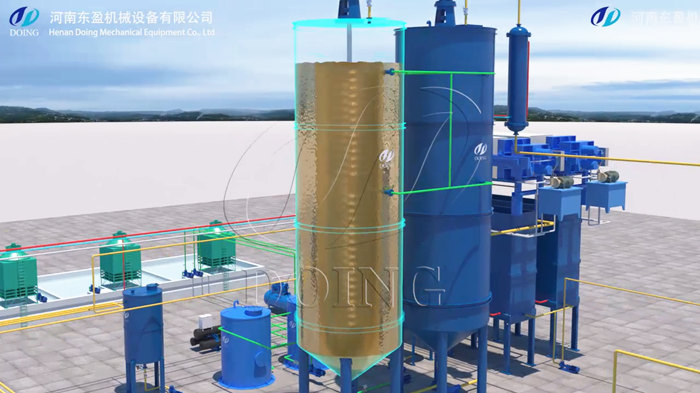

The design process of our 10 tons per day palm oil processing machine contains two crystallization tanks, one is used to heat the crude oil to melt the crystals in the crude oil, so as to avoid affecting the quality of stearin and olein after fractionation. We will use a refrigeration unit to provide frozen water for the crystallization tank to reduce the temperature of the oil. After reaching about 5-6 degrees, we will pump the oil into the filter through the pipeline to filter out the stearin in the oil. There will be a stearin tank under the filter to store the hard fat, and the upper part of the stearin tank there are blades to divide the stearin into small pieces to prevent it from falling from the filter and damaging the equipment. There is a heating coil at the bottom of our stearin tank, which can heat the hard fat into a liquid state, which helps the pump to drive the hard fat outside, and the filtered olein will be pumped into the outdoor olein tank.

Crystallization tank

Crystallization tank

Our frozen water tank is divided two part, one part is used to store the hot water from the crystallization tank, because the temperature of the frozen water will rise after entering the crystallization tank, and the other part is used to store the frozen water with a lower temperature, and energy saving is realized by alternating cold and heat. In addition, we also have an oil cleaning tank, the oil cleaning tank is also divided into two parts, one part is used to store compressed air, used to blow off the grease on the filter to reduce the loss of your grease, and the other part is used for storage To clean the residual stearin on the filter cloth, the whole production line is fully equipped with low loss and complete process, and the client is very satisfied with our design.

Cooling water tank

Cooling water tank

The second is the strength of our company:

Beside this client also pay attention to the strength of our company, through video call with client I show our company and our factory to him, he believed we are a large-scale professional cooking oil processing machine company. By showing many of our successful project cases, client has more trust in our strength and finally choose us.

Factory of Henan Glory Company

Factory of Henan Glory Company

Besides palm oil processing machine, we are also a professional manufacturer of other types of cooking oil processing machine, such as peanut oil, soybean oil, rapeseed oil, cottonseed oil and so on. We have a professional engineer team that can provide one-to-one customized services to meet your various needs. If you have any needs, please feel free to contact us, contact information: +86 13526627860.