A Lebanese customer purchased 2-3 tons per hour palm kernel separation equipment from Henan Glory Company

June 11, 2022 16:32/ DOING News/ leave a messageOn June 1, 2022, a customer from Lebanon purchased a set of 2-3 tons per hour palm kernel separation equipment from Henan Glory Company. The project location is in Sierra Leone.

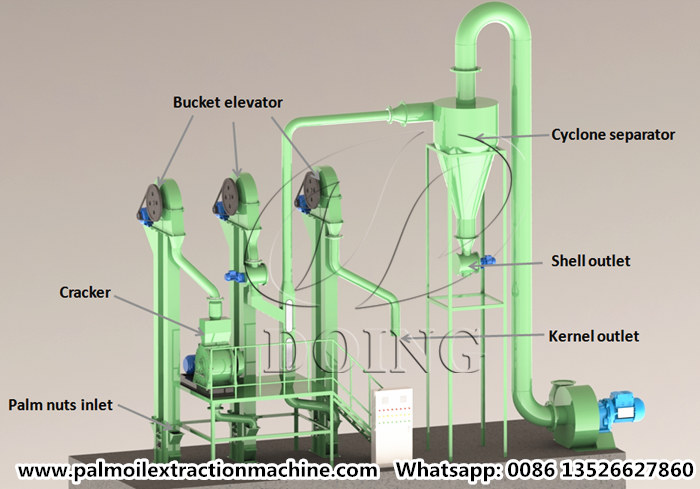

2-3 tons per hour palm kernel separation equipment

2-3 tons per hour palm kernel separation equipment

This customer has a company in Lebanon and has rich experience in international trade. But this is the first time he does palm oil-related business, so he is more concerned about the quality of the equipment, saying that if the quality of the equipment is good, he will buy more equipment in the future. The client understands that the international market demand for palm oil and palm kernel oil is increasing, especially palm kernel oil. But because it is the first time to do this business, he wants to use the palm kernel separation equipment to obtain palm kernels and sell them to others, and then buy the palm kernel oil pressing machine and palm oil pressing machine when he makes money later. The customer also investigated some local equipment, but the quality of the palm kernels obtained was poor, most of them were broken, and they could not be sold at a good price.

In order to solve the needs of customers, we recommend our 2-3 tons per hour palm kernel separation equipment to customers, our 2-3 tons per hour palm kernel separation equipment, which consists of sheller and cyclone wind filter. Because the size of the palm kernel is different, in order to improve the shelling rate and the shelling effect, our shelling machine can adjust the distance between the tooth plate and the beater, so that the integrity of the kernel can be ensured on the basis of breaking the shell. Due to the large difference in weight between the broken husk and the intact palm kernel, adjusting the wind of the cyclone can remove the lighter husk and leave the intact palm kernel. Therefore, the shelling rate and separation rate of our 2-3 tons per hour palm kernel separation equipment can reach 95%-98%.

Palm kernel separation equipment prototype

Palm kernel separation equipment prototype

There are still many manufacturers who use the traditional process to crush the palm nuts to obtain a mixture of palm kernel and shell, and then pour it into a large water tank. Using the difference in density between the shell and the palm kernel, the lighter shell will float on the water. At the bottom of the tank are palm kernels. However, the moisture content of the palm kernel obtained in this way is too high, and it is not easy to store and press. If a drying box is used to remove moisture, the overall equipment investment cost is too high, which is not suitable for customers who are doing this business for the first time.

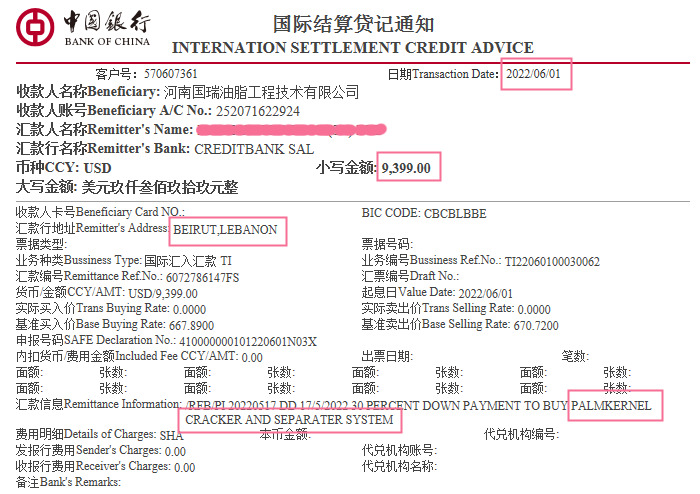

After the customer learned about our equipment and craftsmanship, he liked it very much, so he asked us to provide him with a proforma invoice, and soon received the customer's deposit. The production time of this equipment is about 3 weeks. But before shipping, we also pre-assemble the equipment to make sure that the whole equipment can operate normally without any problems.

Palm kernel separation equipment bank slip

Palm kernel separation equipment bank slip

In addition to palm kernel oil and palm oil processing equipment, we also produce peanut oil, sunflower oil, soybean oil and other oil production equipment. If you want to know more oil production equipment, please contact us.