30tpd palm oil refining machine will sell to Uganda

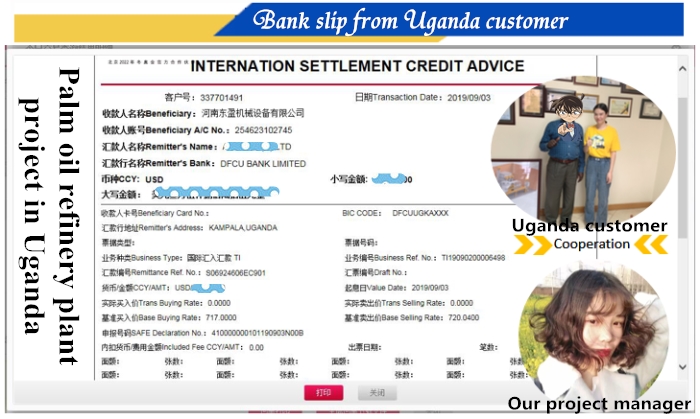

November 27, 2019 11:36/ DOING News/ leave a messageGood news, we successfully signed the 30 tons/day palm oil refining and fractionation plant project contract with Uganda customer. Another happy thing is that we received the bank slip from Uganda customer.

Henan Doing Company successfully received the bank slip from Ugandan customer

Henan Doing Company successfully received the bank slip from Ugandan customer

Two month ago, we received an enquiry from a Ugandan customer. He asked could you please only provide deacidification and deodorization towers in palm oil refining machine. At first we were confused, because most of our customers who send enquiries to us is to learn about the whole palm oil refining machine instead of single deacidification and deodorization tower. In the subsequent further communication with the customer, we learned the following information:

1, A few years ago, our Ugandan customers bought 30tpd batch type CPO refining machine from India palm oil refining machine manufacturer, but the actual production is only 20tons per day.

2, The chemical refining consumption is too big, and the deodorization effect is also not very good.

3, The customer decided to upgrade and transform batch type palm oil refining machine into physical semi-continuous refining machine.

4, The Ugandan customer has a certain understanding of the refining process. He wants to add only a deacidification & deodorization tower to realize his purpose.

Ugandan customer's existing 30tpd palm oil refinery plant

Ugandan customer's existing 30tpd palm oil refinery plant

After learn that, we fully understand the users purpose. After confirmation of various information, our engineers told him, we can do it. In order to design a more reasonable plant plan, equipment layout plan and palm oil refining process plan. Our palm oil processing machine engineers made a request to the customer whether they could go to the site to check the specific situation of the project. Customers also understand this and actively arrange for our engineers' airfare and accommodation. According to the agreement, our engineers also arrived at the customer's factory on time. The following are some of the photos taken by our engineers on site.

[Remarks: We generally only provide indoor equipment. For pipeline connection in outdoor public areas, it is necessary to measure and inspect according to the customer's actual situation before designing drawings.]

Our engineers are measuring and recording various data in Ugandan customer's factory

Our engineers are measuring and recording various data in Ugandan customer's factory

By reading this article, I believe that you have a new understanding of DOING Company. No matter you want to set up a new palm oil refinery plant or you only want to upgrade your existing palm oil refinery plant. Henan Doing Company all can provide the most suitable palm oil refining solutions for you. More detailed information, welcome to contact us.[Related reading: 5tpd palm oil refining and fractionation plant was built in Nigeria ]