How much does it cost do set up an edible oil refinery plant?

May 16, 2019 17:28/ Industry News/ leave a messageThe total cost of setting up an edible oil refinery plant covers a lots of aspects. It includes edible oil refining machine cost, transportation cost, installation and commissioning cost, engineers cost, workers cost, water, electricity, steam cost, raw materials cost, machinery maintenance cost, and so on.

This picture show us the main cost of edible oil refinery plant

This picture show us the main cost of edible oil refinery plant

As a experienced professional edible oil refining machine manufacturer. Henan Doing Machinery will tell you how to calculate the cost of running an edible oil refinery plant.

Assume the customer already has the factory. In the following process, we won't think about the cost of building the factory. From buy edible oil refining machine to sell edible oil to market, the following cost is essential.

From buy edible oil refining machine to transportation it to customer's factory, the main cost includes: edible oil refining machine cost, shipment cost and customer clearance cost.

For the equipment cost, different edible oil refining process, different capacity, different equipment, different price. If you want to know the exact price of edible oil refining machine, welcome contact us and tell us your capacity needs, then we can offer customized equipment unit and detailed quotation. As an experienced manufacturer of edible oil refining machine, we will help you choose the best refining process and equipment according to your processing capacity and your budget.

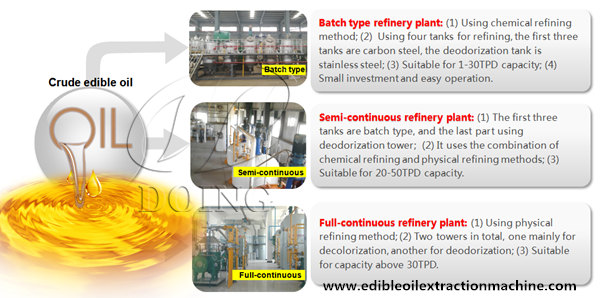

In the edible oil refining market, mainly three types edible oil refining machine can be choose.

Small Scale Edible Oil Refinery (1-20ton/day )

Medium Scale Edible Oil Refinery (20-50ton/day )

Large Scale Continuous Edible Oil Refinery (50-1000ton/day)

Different tyeps edible oil refining machine

Different tyeps edible oil refining machine

Transportation Cost of Edible oil refining machine:

You should know that the transportation expense fluctuate over time. Contact and tell us your location, then we can help you calculate the shipment cost to your factory.

Customer clearance cost;

As for customer clearance cost, it is easy to understand. It is the cost of the customer take away the purchased equipment from the customs.

After the edible oil refining machines were transported to the customer's factory, we need to think about the installation and commissioning cost, engineers cost, workers cost.

Cost of Installation and Commissioning

It includes the cost for project engineers sent by the edible oil refining machine manufacturer and the cost for construction workers hired locally.

After the edible oil refinery plant finished the installation, you need to consider raw materials cost, water, electricity, steam cost, and so on.

The raw materials cost: It is the cost of buying crude edible oil from cooking oil mills or crude edible oil market.

Electricity Cost: If the electricity power to run edible oil refinery plant is obtained from local electricity plant and the costs are calculated from the hours of operation. But the electricity power is supplied by the edible oil refinery plant itself, then the cost need to be calculated separately.

Water cost: During edible oil refining process, we need to consume amount of water. It will also spend some money.

Fuel Cost: The fuel cost is proportional to the number of operational days.

The above is the main cost of running an edible oil refinery plant. If you still have questions about edible oil refinery plant, please send you questions and needs directly, we will answer as soon as possible.

Maybe it is important for most people who want to start an edible oil refinery plant. Different types edible oil refining machine application and features.

Batch Type - Mini/Small Scale Edible Oil Refining Machine;

Capacity: 1~20T/D

Features:

Low Investment Cost & cover a small area ;

Easy Operation & Full Oil Refining Functions;

Semi-continuous Type - Small to Medium Oil Refining Equipment;

Capacity: 10 ~50T/D

Features:

Much efficient than batch edible oil refining machine

Requires more cost

Continuous Type - Large Scale Edible Oil Refining machine

Capacity: 30T/D above

Features:

Automatic and continuous oil refining process

Requires large investment and covers large space