Palm kernel oil production process and profit

July 20, 2018 11:32/ Industry News/ leave a message

The article tells us the viability of the palm kernel oil processing business. We see that the demand for Crude Palm Kernel Oil (CPKO), palm-kernel Cake (PKC) and Palm Kernel Sludge (PKS) in the market is very Huge, and as a matter of fact, the demand for it is all year round plus the profit in this business is amazingly good.

Pure palm kernel

Oil palm is the main oil crop in the tropical and subtropical region. Palm fruit is the most productive oil in the world. Palm pulp has 46 % ~ 50 % oil and palm kernel has 45 % ~ 50 % of oil. The oil extracted from palm fruit is called Palm Oil (PO), while, the oil obtained from palm kernel is called Palm Kernel Oil (PKO). They are two distinct oils and the extraction processes are also different. Below is the detailed information about how to extraction pko from palm kernel.

For different production capacity, we provide different types of palm kernel oil extraction machines. Below is our small scale palm kernel oil extraction line that is specially designed to extract oil from palm kernel. It is mainly composed of palm nut cracking and separating machine, palm kernel cleaning machine, palm kernel crushing machine, palm kernel cooking machine, palm kernel pressing machine, crude palm kernel oil filtering machine, etc.

Palm kernel oil production machine

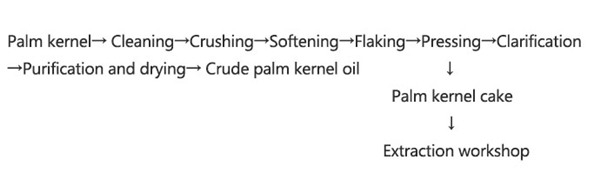

Palm kernel oil production process as follows:

Palm kernel oil production process flow chart

Equipments which directly related to the palm kernel oil extraction process are as follows:

Palm nut cracking and separating station:This palm nuts cracking and separating machine is specially and newly developed to be used for cracking and separating palm nuts. It consists of palm nuts cracking machine and palm nuts kernel separator machine. The palm nuts cracking machine is mainly applicable for dividing the palm kernels into the outer hard shell with high efficiency. The separating machine is for separating the palm nuts kernels from the cracked shells clearly and completely. There are two different types with capacity of 200-300kg/h and 1000kg/h as your choice.

Palm kernel cleaning station: It is used for removing the iron impurities, stone, fiber and pthers. These impurities are bad for automatic palm kernel oil production line, especial for the palm kernel oil expeller.

Palm kernel crushing station: because the palm kernel is hard and big size, it is required to crash to smaller and even pieces. If once crashing can not reach the requirements, the second crashing is required.

Palm kernel softening station:Softening adjusts moisture and temperature of oil seeds, softens and increases plasticity of oil seeds. For palm kernel, softenning is an essential process for better flaking effect.

Palm kernel flaking station: Flaking creats beneficial condition for cooking.

Palm kernel cooking station:Cooking is to wet, heat, steam and to cook flakes to change the internal structure of flakes, including destorying cells, protein solidification and denaturation, etc. All these changes makes oil easy to isolate and also enhance crude oil quality.

Palm kernel pressing station: Palm kernel oil press machine is to press oil from oil seeds ,Basically we can get most of the palm kernel oil.

Palm kernel filtering station: After pressing, there are some oil dregs in the crude oil, after clarifying, we need to filter the crude oil to avoid to jam the oil pipes during palm kernel oil refining processes.

I won’t write further about the business as the article referenced above is self explanatory. However, I present below the production process, machinery requirement and an updated profitability analysis of the business.

Profitability

1 tone of palm-kernel nuts gives an average of 410liters of oil, 540Kg of cake, and 25Kg of sludge.

Average price for 1tone of palm-kernel nuts is N70,000.

Average Selling Price of the products is

»Oil = N200 per litre

»Cake = N15 per Kg

»Sludge = N20 per Kg.

So if you process 1tone, you sell:

»Oil : N200 x 410 = N82,000

»Cake : N15 x 540 = N8,100

»Sludge : N20 x 25 = N500

Total sales = N90,600.

Profit = N90,600 – N70,000= N20,000

The above profit is for processing 1tone of palm kernel.

Now, if you process 2 tone per day, you get N20,000 x 2 = N40,000 per day as profit, which by extension implies a monthly profit of N1,120,000 (24days). Profit increases as production increases.

Note: If you sell your products at a bit lesser price, you will generate much more sales and still make a reasonable profit. If you are a good negotiator, you can get the nuts as low as N(60,000 – 65,000) per ton.

CONCLUSION

Palm kernel processing business is lucrative and the market for the products is vast. It even extends to the international market. Get buyers, offer them good quality products at competitive prices, and that’s it.

If you have much capital to process large quantity continuously, visit http://www.palmoilextractionmachine.com for more infromation about palm kernel oil processing plant cost and project case.