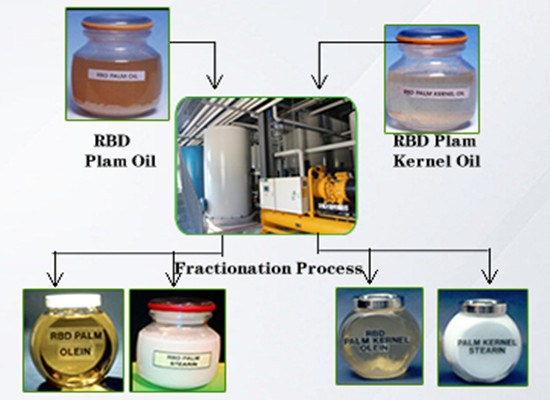

Palm oil fractionation process

September 29, 2017 18:31/ Industry News/ leave a message

Palm oil fractionation plant

The crystallization process follows in the palm oil fractionation process. This process involves the removal of high-melting glycerides that would cause the liquid oils to become viscous and cloudy at room temperatures.

There are three most important factors in palm oil fractionation process : time, agitation and temperature. Low temperatures will cause the components to separate due to supersaturation while formation of smaller crystals will be facilitated by agitation. With gradual decreases in temperatures, longer crystals will be formed with time.

Henan Doing Company Palm Oil Fractionation process system is designed to process crude, pre-treated or RBD palm oil. The process is divided in few steps as below.

Feed oil heating

Crystal formation under controlled cooling

Crystal growth

Crystal maturation

Filtration

Palm oil fractionation process

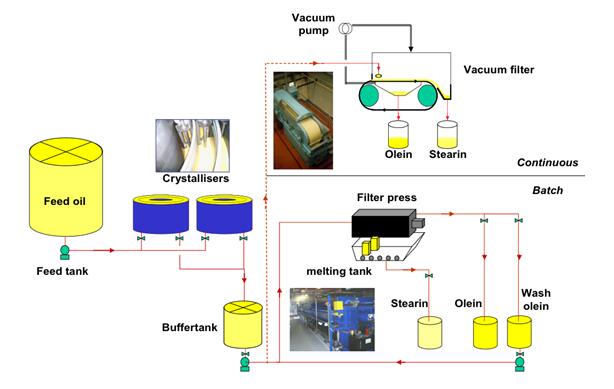

Dry Fractionation is a process to separate vegetable oils such as palm oil into two fractions, Olein and Stearin, by the crystallization properties of the oils. A typical dry fractionation plant consists of Crystallization Section and Filtration Section.

Crystallization Section

Preheated RBD palm oil is fed into the Henan Doing Company crystallizers and then cooled in a controlled environment to form crystals. The cooling sequence follows a defined program using PLC or programmable controllers. The slurry of crystals and oil is then pumped to the fractionation filter for separation of the solid crystals from the oil.

Filtration Section

In the filtration section, an automated membrane filter press is usually used for filtration of oil slurry to separate the stearin crystals from the liquid olein. Stearin is retained as filter cake while olein passes through the filter as filtrate. Olein yield is maximized by squeezing the stearin cake through inflation of the membrane with air or liquid.

Henan Doing Company is able to provide specific palm oil fractionation process solution meeting customers’ requests.If u are interested in palm oil fractionation plant,please feel free to contact us!