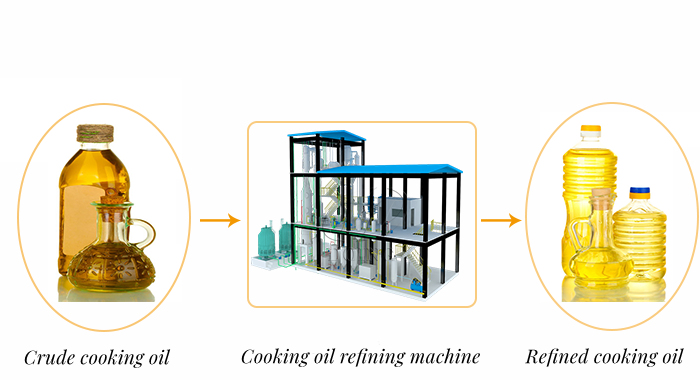

How to get vegetable oil from crude cooking oil?

November 16, 2022 13:21/ Industry News/ leave a messageCrude cooking oil generally refers to the cooking oil containing certain impurities extracted from vegetable oils in the leaching or pressing process. The main component of crude cooking oil is a mixture of fatty acid triglycerides (commonly known as neutral oil). In addition to neutral oil, crude cooking oil also contains non-glyceride substances (collectively referred to as impurities). Their types, properties, and states can be roughly divided into three categories: mechanical impurities, fat-soluble impurities, and water-soluble impurities.

Refined cooking oil

Refined cooking oil

1. Subsidence method

Natural sedimentation separation under the action of gravity is a simple and commonly used separation method. The sedimentation method is to use the density difference between the suspended impurities and the oil, and under the natural static condition, the suspended impurities will settle down from the cooking oil and be separated from the cooking oil. The equipment used is simple, but this method has a long settling time and low efficiency, and is rarely used in production practice.

2. Filtration method

With the help of gravity, pressure, vacuum or centrifugal force, the method of using filter cloth to filter under certain temperature conditions is collectively referred to as the filtration method.

3. Centrifugal separation method

The method of filtering and separating or settling and separating oil residue by centrifugal force is called centrifugal separation method. The effect of centrifugal separation is good, the production is continuous, and the processing capacity is large.

4. Refining method

Crude cooking oil obtained by pressing or leaching is usually processed with cooking oil refining machine, and the crude cooking oil is refined through degumming, deacidification, decolorization, deodorization and other processes.

Cooking oil refining machine

Cooking oil refining machine

Degumming is the process of removing colloids such as phospholipids contained in crude cooking oil. There is a certain amount of free fatty acids in all kinds of unrefined crude cooking oil. The process of removing free fatty acids in cooking oil is called deacidification, and the method of deacidification is alkali refining. Distillation, solvent extraction, etc. There are many methods for oil decolorization. The oil decolorization method widely used in industrial production is adsorption decolorization. In addition, there are heating decolorization, oxidation decolorization, and chemical reagent decolorization. There are several methods for oil deodorization, such as vacuum steam deodorization method, gas blowing method, hydrogenation method, polymerization method and chemical deodorization method.

Cooking oil refining machine is usually used in production to process crude cooking oil. Henan Glory Company specializes in the production of cooking oil refining machine. We are committed to providing customers with one-stop service and one-to-one customized service. You are welcome to come to consult.