Feasibility of setting up a palm oil processing plant

June 6, 2018 16:09/ Industry News/ leave a message

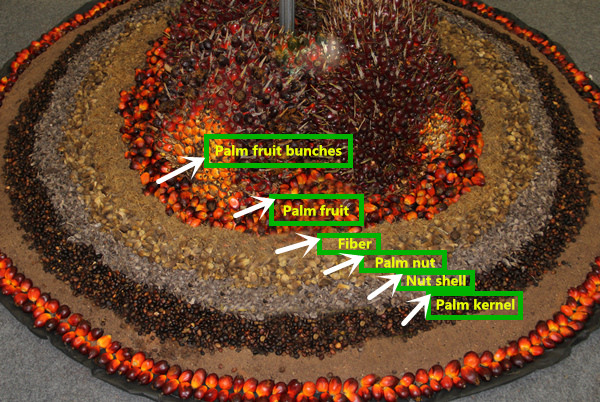

Palm fruit

Application of palm oil

Opportunity

First, you need to identify if there is a business opportunity in a given area, country or region. A growing demand for palm oil provides an economic opportunity. The abundance of palm trees guarantees a continuous supply of palm fruits. Palm oil processing is labor intensive. The youthful workforce provides cheap labor depending on area of operation. There should also be an opportunity to manufacture further refined products.

Technical Feasibility

Advanced methods of production require new palm oil processing equipment which can be expensive. You need palm fruit reception machine, palm fruit sterilizing machine, palm fruit threshing machine, palm fruit digesting & pressing machine, crude palm oil clarification machine and others. High costs can discourage intending processors from investing and setting up new palm oil mill plants. You can choose to hire palm oil processing equipment. But you must expect some delays during the processing period. There needs to be adequate infrastructure like roads for moving final products and machines. A piece of land is also required for setting up the plant. Adequate space is required away from residential areas. There should be a constant supply of palm fruits, or you can choose to cultivate your own farm.

Financial Feasibility

Setting up the palm oil processing plant and purchasing equipment requires funds. It also takes into consideration wages and salaries to be paid to employees. Available funds determine the size of the plant and amount of palm oil produced. Economic stability and profitability of palm processing need to be analyzed. There should be demand for palm oil to guarantee profits in the long run. A feasibility study will help determine if the business plan has enough resources to fund the project. Financial implications of oil processing form the basis of the processing business. Palm oil economics uses profitability models like Benefit-Cost Ratio to determine the cost of palm fruits, transportation, hiring/purchasing equipment, availability of labor and market price.

Environmental Feasibility

An environmental impact assessment needs to be carried out as provided by the law. It helps to determine any negative impacts when establishing and operating the plant. Fortunately, all by-products from a palm oil processing plant are recyclable. Palm shells can be used to make renewable energy fuel pellets. Boiler ash is used as a cleaning agent or fertilizer. A social impact assessment is also done to determine the level of poverty elevation, job creation and any disturbance to the local people.

In conclusion, a financially, technically and environmentally feasible project benefits all whenever an opportunity presents itself. The owner of the palm oil processing plant will earn profits. Local people will get jobs, palm oil, and refined products. The products are also recyclable. Carrying out a feasibility study and following laws of the land determines the success of a palm oil processing enterprise.

Palm oil processing plant introduction :

The palm oil is the world's second largest edible vegetable oil, only ranking after soybean oil. At present, Malaysia and Indonesia is two largest palm oil producing countries in the world. Besides, there are many palm oil processing plants in Africa, such as Nigeria, Ethiopia, Congo, Ivory Coast etc.

Our company is professional in manufacturing palm oil processing plant for years. At present, we research and design a new technology of palm oil processing plant, based on our rich experience in palm oil plant.

Complete set palm oil processing plant

The following is detail introduction of our new technology- palm oil processing plant.

1. Sterilizing section:

The purpose is to destroy lipase in the flesh palm fruit and avoid the content of FFA in oil further increase. The use of high temperatures to cook soft fruit bunches and sterilization (145 ℃ ,90-120 minutes), easy to separate fruit bunches fruit, soft fruit, increasing the humidity of the fruit.

Palm fruit sterilizing machine

2. Threshing section:

FFB has softened in sterilization process. After machine and screening beating off the fruit, palm fruit and empty fruit bunches (EFB) separation.

Palm fruit threshing machine

3. Digesting section:

It is used for heating and cooking the palm fruit, to make it suitable for pressing, doing like this can help final user get the maximum oil and good quality cakes.

Palm fruit digesting machine

4. Pressing section:

we select the best quality palm oil processing plant in domestic, it is improved on the base of YL series palm oil expellers, the service life is more longer, the operation cost is low, and the cake is loose but not splintery, the most important is the oil residue is low.

Palm fruit pressing machine

5. Filtering section:

After pressing by palm oil processing plant, there are some oil dregs in the crude oil. And after clarifying, we need to filter the crude oil to avoid to jam the oil pipes during refining processes.

Crude palm oil clarification machine

Our company is one leading producer of palm oil processing plants in China, also one unit exempt from quality examination. We are committed to bringing in new technology, renewing products, keeping leading in this filed. If you have any questions about the palm oil processing plants, please feel free to contact us!