Vegetable oil processing steps

April 12, 2018 18:01/ Industry News/ leave a message

Vegetable oil processing plant

Henan Doing Company is one of the best vegetable oil processing manufacturer which provides you the best equipments and quality. They use the best vegetable oil processing technology in the cooking oil industry.

Complete set vegetable oil processing steps are cooking oil pretreatment & pressing machine ,cooking oil solvent extraction machine ,cooking oil refining machine.Next i will introduce cooking oil production process to everyone who interested in vegetable oil production machine.

Description of cooking oil pretreatment & pressing machine:

3D animation of vegetable oil production machine

Oilseed pretreatment & pressing machines is important section to remove impurity, regulate moisture and temperature, break oilseeds into small particles to change oilseed molecular structure,etc. Pretreatment standard is important for the following oilseeds solvent extraction process , which influences final oil quality.

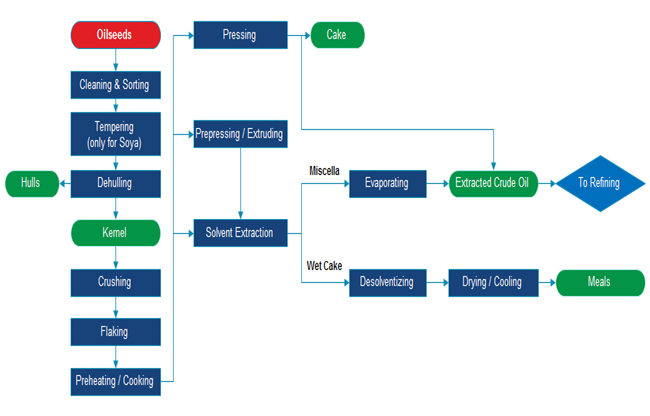

Vegetable edible oil pressing process flow diagram:

Vegetable oil processing process

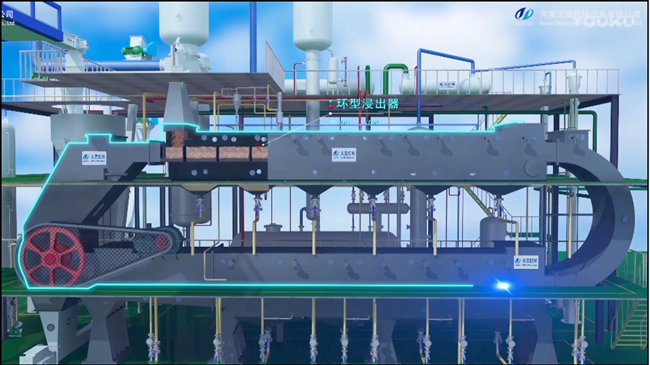

3D animation of vegetable oil extraction plant

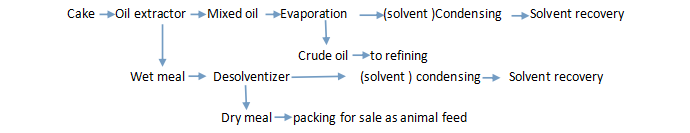

Solvent Extraction is a process involving the injection of Hexane into the oil bearing cells of seeds resulting in a mix of oil and solvent, the so called miscella. The Hexane will be evaporated later from the miscella resulting in unrefined oil. By condensing the Hexane it can be recycled and used over and over again.

Vegetable edible oil extraction process flow diagram:

Vegetable oil extraction process

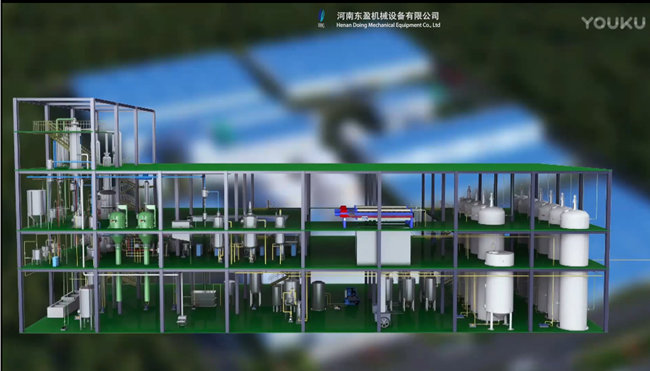

3D animation of vegetable oil refining machine

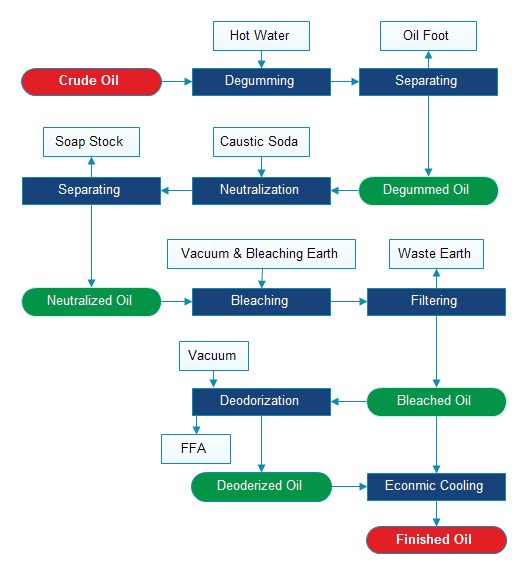

Different raw material,the refinery process is little different.such as for peanut,soybean,cotton seed,sesame,castor,rapeseed etc,the refinery process has four steps:degumming,deacidification,decolorization and deodorization.

For corn germ,rice bran,sunflower seed,palm oil,the refinery process has five steps:degumming,deacidification,decolorization,deodorization and dewaxing(also called fractionation for palm oil).

Vegetable edible oil refinery process flow diagram:

Vegetable oil refining process

Cooking oil pretreatment & pressing :

1, 5-30T/D small scale cooking oil pretreatment & pre-press production line

2, 30-500 T/D medium-sized cooking oil pretreatment & pre-press production line

3, 500-2000T/D large-scale cooking oil pretreatment & pre-press production line

Cookig oil solvent extraction:

30-500T/D cooking oil solvent extraction production line;

500-2000T/D cooking oil solvent extraction production line;

Cooking oil refining:

1-2-3-5-10TPD batch cooking oil refinery machine;

10-15-20-25-30-50TPD semi continuous cooking oil refinery machine;

50-80-100-150-300-600TPD full continuous cooking oil refinery machine;