Palm oil refinery plant

Palm oil production process

Oil refining is based on the different usage and requirements, utilizing the physical methods and chemical processes to get rid of the harmful impurities and needless substance in the crude palm oil, getting standard palm oil.So palm oil refining machine is the major equipment to refine crude palm oil.

Palm oil refinery plant is a way to get rid of the harmful impurities and needless substance in the crude oil, aims at improving the oil storage stability,flavor and color.then get standard edible oil or provides qualified material for deep processing.Palm oil refinery process usually includes the following sections: degumming and deacidification, decolorization, and deodorization.

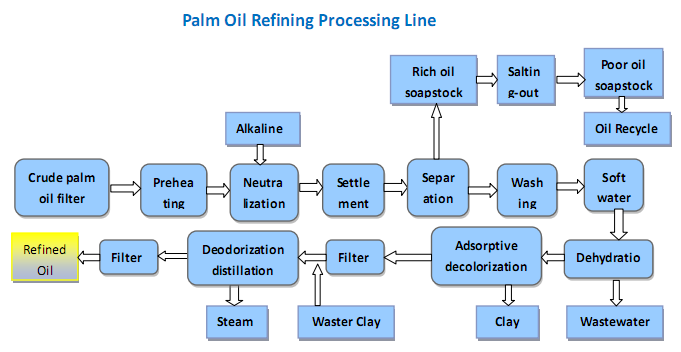

Process flow chart of palm oil refinery plant:

Crude palm oil →Degumming → Deacidification → Decolorization →Deodorization → (Winterization/Fractionation) → Standard edible oil

Palm oil refining process

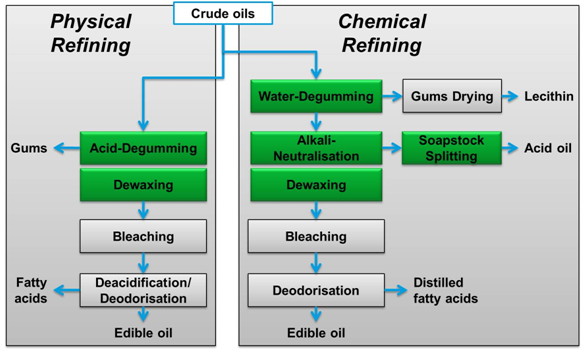

There are two refining methods for the vegetable oil refining in the edible oil refinery plant. They are physical refining and chemical refining. Physical refining means removing gum in oil during process of degumming in special method and removing FFA in process of deodorizing by steam. Chemical refining, however, means removing FFA in a chemical way ( Acid-base neutralization). Gum and soap foot produced is separated by centrifuges.

Vegetable oil refining - Chemical Refining

1.The finished edible oil is consistent and stable.

2.Excellent adaptability and less requirement to oil quality.

3.Less bleaching earth is added into compared with physical refining.

Vegetable oil refining - Physical Refining

1.High oil refining rate, less oil loss.

2.No waste water discharged.

3.Especially suitable for oils of high acid value, and low gum content.

4.More FFA distilled out.

Physical refining and chemical refining

Equipment of palm oil reifnery plant:

Degumming section of crude palm oil refinery:

Degumming is the first and basic step in the crude palm oil refinery plant, degumming process aims to removing the gum impurities in the crude oil to make it suitable for further refinery process, hydration degumming and special acid degumming are the two main methods.

Deacidification section of crude palm oil refinery:

The deacidification system uses versatile neutralization technology, which is developed to deal with oilseeds of different species and qualities in the oil refining plant, it can realize both degumming and neutralization processes by adding alkali, water and acid, then with FFA, crude phospholipids and moisture all removed, the oil and by products (soap foot, phospholipids) are separated.

Bleaching section of crude palm oil refinery:

The oil bleaching is also named decolorization in oil refinery processes. This process’s main purpose is to remove the product of oxidation, pigments, phospholipids, soap materials from the oil. In the oil refinery plant, this process can improve the oil color as well as supplies high quality oil for the deodorization process.

Deodorization section of crude palm oil refinry:

Deodorization section is very crucial in edible oil refinery plant in first grade oil production as it improves the flavor of the oil; the quality of deodorization equipment has great effect to the oil quality.

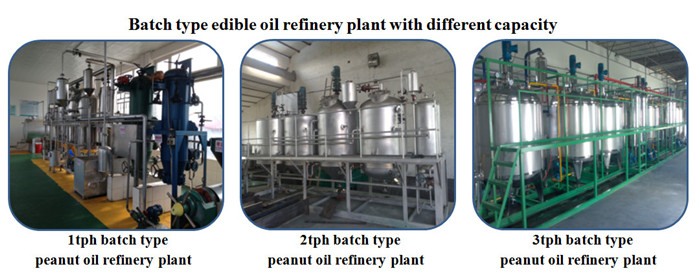

Diffrent types palm oil refinery plant