Rapeseed oil mill plant

Rapeseed oil mill plant

As manufacturer of rapeseed oil mill plant, we can offer whole line or parts of rapeseed oil mill plant with general capacity from 10TPD to 1000TPD. For special capacity, our engineers can also help you design and install workshop according to your capacity and requirements.

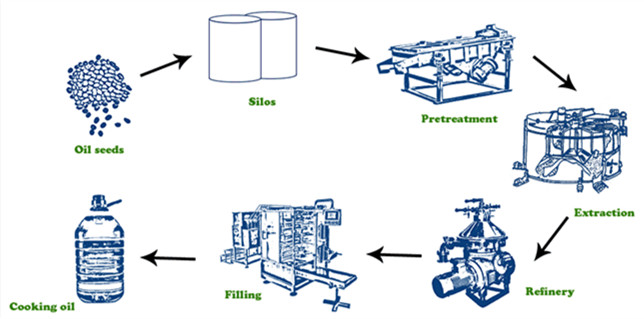

Next we will introduce the wholr rapeseed oil mill plant from rapeseeds to rapeseed oil.

Rapeseed oil introduction:

Rapeseed oil is a key ingredient in many foods. Its reputation as a healthy oil has created high demand in markets around the world, and overall it is the third most widely consumed vegetable oil in the world.

Rapeseeds

The main processes of rapeseed oil extraction machine as below:

Rapeseed oil pretreatment machine

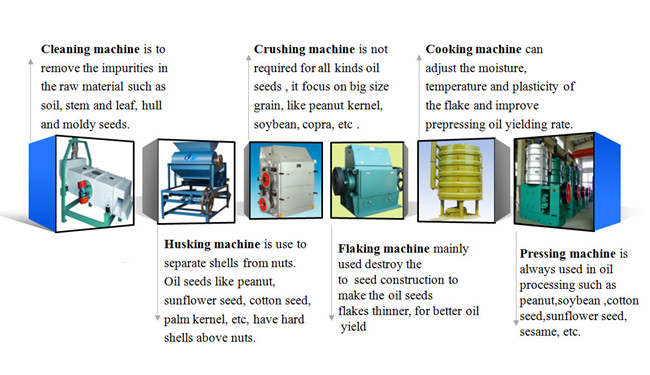

1.Cleaning

Use the vibration screen and gravity stoner as well ase the dust removing wind net to obtain high effective cleaning, ensure good work condition and production stability.

2. Flaking

Flaking means a certainty granularity of seed was prepared for flaked of about 0.3 mm, the oil of raw material can be extracted in the shortest time and maximum, and

residual oil was less than 1%.

3. Cooking

This process is heating and cooking for rapeseed seeds which is easy to separate of oil and can provide the oil quantity from pre-press machine.It is easy to operate and have long life.

Rapeseed oil extraction machine

1.Extraction process

The pre-pressed cake or flake, firstly enter into the sealed scraper blade to avoid the solvent gas escaping because of the section without screw blade in the sealed auger. Rapeseed seeds enter into the box-chained loop type extractor counter-currenting with the solvent, the grease is extracted. Miscella condensity increase from 2% to more than 25%. Miscella discharged from extractor and into miscella filter, then the leached meal in the miscella tank enter into evaporation system through 1st evaporation feed pump and finally drop-in DTDC out from wet meal drag conveyor.

2.Evaporation process(DTDC process)

Using the secondary steam desolventized from DTC desolventizer and produced by steam-jet pump to heat and evaporate micella in the first long-tube evaporator. Export temperature reaches to 58-62℃ and condensity reaches to more than 65%. Then, micella enters into the second long-tube evaporator in which the temperature is heated to 105-110℃ by indirect steam and the condensity reaches to more than 95%. Then miscella enters into stripper in which residual solvent in oil will be removed, the export temperature reaches to about 105℃ and the general volatile of the extracted crude oil is less than 0.30%.

3.Desolventizing process

Rapeseed Wet meals discharged from the bottom of extractor enter the top of DTDC and land on the predesolventizing trayers where thery are heated by the indirect steam, thus, some solvent in meal is evaporated and meal temperature is risen; Predesolventized meals land on predesolventizing trayers where they use the second steam in desolventizing trayers to predesolventize solvent from meal, then, meals enter desolventizing layers in which direct steam is injected.

4.Condensation recovery process

Extractor is equiped with a seperate condenser, 1st and 2nd evaporation share one condenser. Low and high temperature of solvent gas both from 1st and 2nd evaporation enter into the condenser after its neutralization, which greatly reduces the load of condenser and improves the efficiency of condensing. Stripping and analyzing share one condenser, the non-condensable gases from extractor and other condensers enter into the vent gas recovery system through the final condenser.

Rapeseed oil refining machine

Oil refining is according to the different usage and requirements, utilizing the physical methods and chemical processes to get rid of the harmful impurities and needless substance in the crude oil, getting standard oil.

A.Degumming section:

This is the most important section of de-gumming, adding the water (there is a little P-acid in water) to remove the gum.

B.Deacidification section:

Using alkali like (NaOH) to neutralize FFA in oil, during this process it will produce soapstock , then separating it from the oil.

C.Decolorization Section:

Because there is pigment in crude oil, the oil color is dark. In order to lighten oil color, we need to using the white clay to absorb the pigment away, then using vibrating filter to separate the waste clay.

If you want to get light color oil, you need to add more white clay. the oil color can be controlled by clay amount.

D.Deodorization section:

General speaking , the crude oil smells not good, it will affect of oil storage and price. So we usually use the direct steam to take odors. At the meanwhile, there is about 0.5% water content in refined oil, because the high temperature in the deodorization pot, dehydration is also finished. After that, the final oil will be refined once again through safety filter.

By apply the above process, you can get the standard high quality rapeseed oil.