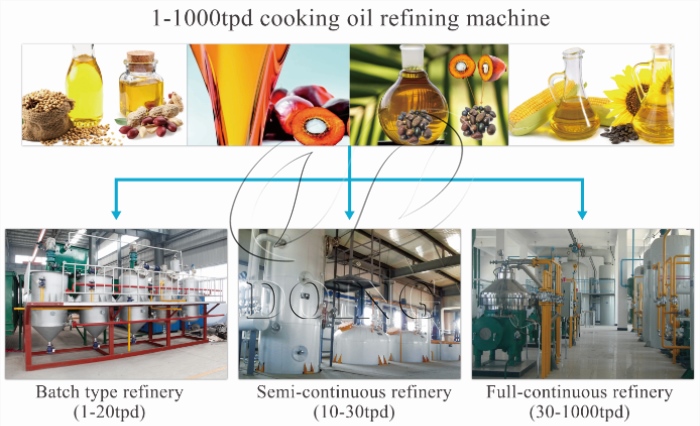

Fully automatic continuous soybean oil refining machine

Henan Doing Company is specialized in soybean oil refining machine. We can provide the soybean oil refining machine from 1 ton to 1000 tons. In general, batch type soybean oil refining machine is with capacity 1-20TPD; The semi-continuous soybean oil refining machine is suggested with capacity from 20-50TPD; And continuous soybean oil refining machine is used for capacity above 50TPD. Of course, this is only a rough suggestion, for reference only. Once you decided to buy soybean oil refining machine from Henan Doing Company, Our engineer can help you design the whole soybean oil refining machine according to your capacity and requirements.

There are three types soybean oil refining machine can be selected in soybean oil processing process

There are three types soybean oil refining machine can be selected in soybean oil processing process

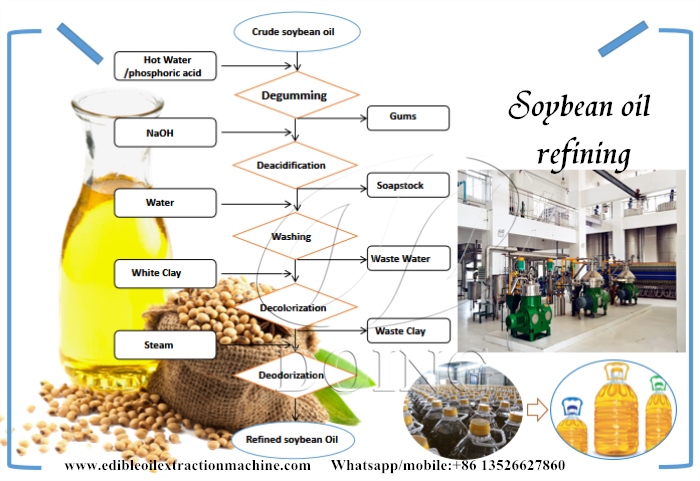

Soybean oil refining steps:

The typical steps in the soybean oil refining line includes Degumming section, Neutralizing section, Decolorization/ Bleaching section, Deodorizing section.

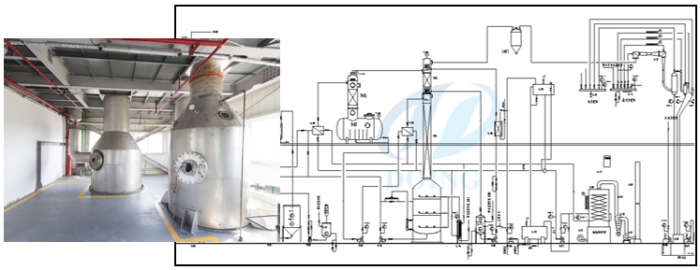

Soybean oil refining process flow chart

Soybean oil refining process flow chart

Main process of fully automatic continuous soybean oil refining machine

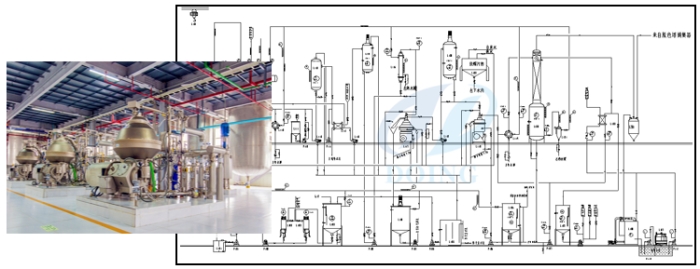

1. Degumming and De-acidification Section:

Soybean oil degumming and de-acidification section uses washing method to separate soap residual from mixing oil, providing preparation for next step soybean oil refinery process.

Degumming and deacidification process flow chart of soybean oil refining machine

Degumming and deacidification process flow chart of soybean oil refining machine

2. De-colorization Section:

Soybean oil de-colorization section is mainly used to remove oil pigment, residual soap and metal ions during soybean oil refinery process.

Decolorization process flow chart of soybean oil refining machine

Decolorization process flow chart of soybean oil refining machine

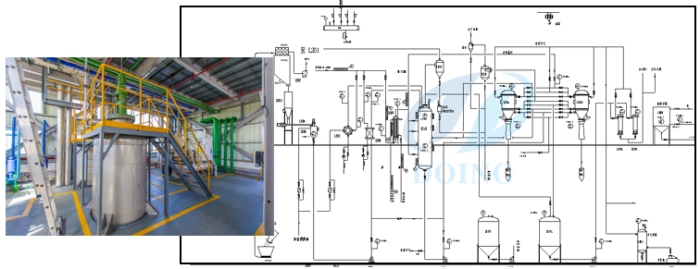

3. Deodorization Section:

Soybean oil deodorization section is the final step of crude soybean oil refinery plant. It plays important part in removing the free fatty acids, ketones, aldehydes and other impurities, besides the pigment composition will be also removed in deodorization tower.

Deodorization process flow chart of soybean oil refining machine

Deodorization process flow chart of soybean oil refining machine

Operation process of fully-continuous soybean oil refining machine:

(1)pump crude soybean oil into refining tank and heat with conduction oil, and the temperature will reach about 70°C-80°C after one hour.

Add acid or alkali to separate according to the acid value. After one hour's processing and 4-6hours deposit, then convey soap stock to storage tank.

(2)Pump refined soybean oil into de-coloring tank. When it is up to 90-110°C after one hour's heating, add clay into tank for 20min's processing. Then separate clay and oil with filter.

(3)Put discolored soybean oil into deodorization tank with vacuum pump. Heat and process with steam for odor removal. After filtering, you will get final oil product.

Economic & technical Index of soybean oil refining machine( degumming, deacidification, bleaching, deodorization)

| Power consumption | ≤28 KWH/ton oil |

| Steam consumption | ≤360~420 Kg/ton oil |

| White earth consumption | ≤8~20 kg/ ton oil |

| Caustic soda | ≤7 kg/ ton oil(according to crude oil acid |

| Phosphoric acid | ≤1.0 kg/ ton oil |

| Water consumption | Circulating water 60~65t/h |

| Water consumption 0.25~0.3t/ton oil |

Large scale soybean oil refining machine

Large scale soybean oil refining machine

Doing Company has been specialized in soybean oil making machine for decades. And our soybean oil processing machine's technology and quotation are both our advantages to compete with other companies. If you are interested in soybean oil processing machine or soybean oil refinery plant, please feel free to contact us. Our professional engineers can help you design and install according to your capacity and requirements.

Besides soybean oil refining machine we can also offer as follows:

1-1000tpd soybean oil pretreatment & pre-pressing machine;

1-1000tpd soybean oil solvent extraction plant;

1-1000tpd soybean oil refinery plant;

1-2000tpd soybean oil production line;