Soya bean oil processing line

Pretreatment section

Before soya beans enter the soya bean oil pressing machine for soya bean oil processing, they need to go through processes such as cleaning, crushing, softening, flaking, and cooking, which is called soya bean pretreatment process. Adequate pretreatment of soya beans can improve the quality and yield of the soya bean oil. Usually, the soya bean oil pretreatment process is as follows:

Cleaning: In the soya bean oil pretreatment process, we need to use some cleaning machines such as

magnetic selectors, de-stonner and cleaning sieve. These cleaning machines can help remove some impurities such as leaves, stones, sand, dirt, spoiled seeds and metal contaminants.

The picture of magnetic selectors, de-stonner and cleaning sieve

The picture of magnetic selectors, de-stonner and cleaning sieve

Crushing: This process requires a crusher to break the soya beans into small particles.

Flaking: The purpose of flaking is to increase the contact area between the soya beans and the roaster and destroy the internal structure of the soya bean cells, so as to facilitate the soya bean oil pressing machine to press the soya beans.

Cooking: In this process, we need to use a roaster to steam and fry the soya beans after flaking, which can adjust the temperature and moisture of soya beans, as well as achieve the best condition.

After that, we can send the prepared soya beans to the soya bean oil pressing machine to squeeze out soya bean oil.

A set of soya bean oil pretreatment machines

A set of soya bean oil pretreatment machines

Pressing section

The soya bean oil processing by pressing method is to extract the soya bean oil directly from the oilseed by mechanical pressing. The whole process does not contain any chemical additives, ensuring that the product is safe, hygienic, pollution-free, and the natural nutrition is not destroyed. In addition, this process requires the use of a soya bean oil pressing machine. Doing Company’s soya bean oil pressing machine not only has low energy consumption and small footprint, but also has a low residual oil rate, making it the first choice for soya bean oil processing machines.

Soya bean oil pressing machine

Soya bean oil pressing machine

Solvent extraction section

The soya bean cake produced by the pressing process contains residual soya bean oil, which can be extracted by solvent extraction process. The process refers to the use of the miscibility of organic solvents (n-hexane) and oils to extract soya bean oil based on the different boiling points of organic solvents and soya bean oil. After solvent extraction, the residual oil content in soya bean cake is less than 1%. This method is widely used in large-scale commercial operations due to its efficiency. If you want a higher profit or higher processing capacity, you can choose this method. The processing capacity of our soya bean oil solvent extraction plant is from 20 tons to 100 tons per day. The main machines used in this part include extractor, stripping tower, evaporator, oil-water separator, condenser, stripping tower, etc.

Soya bean oil solvent extraction machine

Soya bean oil solvent extraction machine

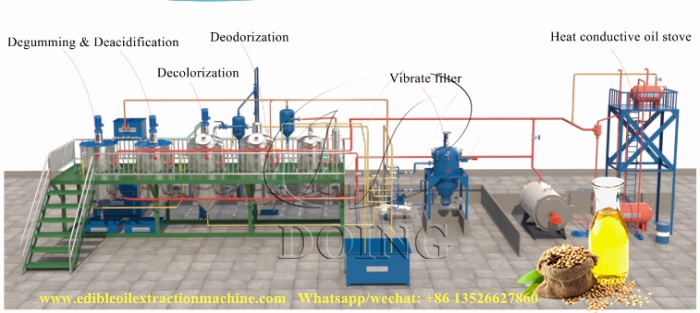

Refining section

Whether soya bean oil is produced by pressing method or solvent extraction method, what we ultimately get is crude soya bean oil. This process is used to remove colloidal impurities, free fatty acids, pigments and odors in crude soya bean oil. The machines required for the soya bean oil refining process includes refining pots, decolorizing pots, deodorizing pots, filters, etc. In this regard, Doing Company can provide intermittent, semi-continuous and fully continuous soya bean oil refining machines. Besides, we can also match the appropriate soya bean oil refining machines for the customer according to the processing capacity of the soya bean oil processing plant.

Soya bean oil refining processing line

Soya bean oil refining processing line

The above are the sections and machines involved in the soya bean oil processing line, but machines are not fixed. Doing Company can increase or decrease the machines according to the processing capacity and detailed requirements of different customers’ soya bean oil processing plants, while ensuring the output efficiency of oil products, and ensuring greater benefits with less investment cost. If you want to know which soya bean oil processing machine corresponds to different processing capacities, please consult Doing Company.