How to make cooking oil from sunflower seeds? What equipment are commonly used in sunflower oil mill plants?

February 23, 2022 14:45/ FAQ/ leave a messageSunflower oil is golden in color, clear and transparent, and has a fragrant smell. It is an important edible oil. It contains a lot of essential unsaturated fatty acids such as linoleic acid, which can promote the regeneration and growth of human cells, protect skin health, and reduce the accumulation of cholesterol in the blood. It is a high-grade nutritional oil. It is golden in color, clear and transparent, and has an aromatic odor. Worldwide consumption of sunflower oil ranks fourth among all vegetable oils after palm oil, soybean oil and rapeseed oil. The global output of sunflower oil is stable between 10 million and 12 million tons, and sunflower oil is one of the important edible oils in European countries. Therefore, more and more people want to understand the production process of sunflower oil and the equipment needed.

Generally, the preparation process of sunflower oil is divided into three steps.

The first is oil extraction - pretreatment and pressing. Sunflower seeds will have a lot of impurities in the process of collection and transportation, so generally, sunflower seeds should be cleaned first. The impurities will affect the oil and damage the machine. Then the shells are peeled and the husks are removed to obtain clean sunflower seed kernels. Then it is crushed, steamed and fried to meet the requirements of temperature and moisture before pressing, and then pressed and filtered to obtain sunflower seed crude oil. The equipment required for this process are: vibrating screen - stone removal machine - magnetic separator - sheller - kernel and nucleus separation - crusher - steaming frying pan - oil press - filter.

Sunflower oil pretreatment and pressing machine

Sunflower oil pretreatment and pressing machine

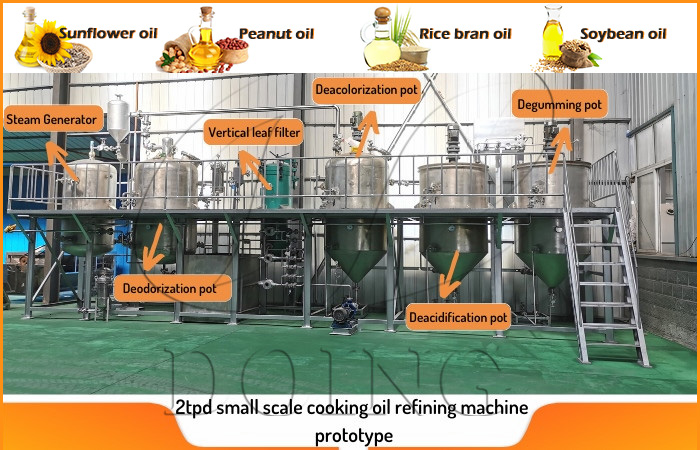

The second is refining - removing harmful substances such as phosphoric acid in the crude oil. Sunflower oil is degummed, deacidified, decolorized and deodorized during the refining process. To obtain clear and odorless refined oil, the edible oil standard required by the state can be obtained. The required equipment is: the refining line includes a neutralization pot for acid refining, alkali refining and water washing--a decolorizing pot for bleaching grease and removing pigments; Oil furnace/electric heating system: provide the heat energy required for production;--vacuum pump: provide the vacuum environment required for decolorization and deodorization;--leaf filter/filter press: filter the clay in the decolorized oil;--air pressure Machine: blow dry decolorized clay; -- steam generator: generate steam required for deodorization and distillation.

Sunflower oil refining machine

Sunflower oil refining machine

And finally there's dewaxing -- removing excess wax from the oil, which tastes better. The method of freezing and prospecting, followed by mechanical separation of the precipitation wax. The resulting oil can be sold for a better price and more popular. The equipment required are: crystallizing tank, refrigeration unit, air compressor and other equipment.

The above process and equipment are the main part of the sunflower oil production process, I hope to help you. As a professional manufacturer of oil equipment research and development, production and sales, we also welcome your consultation. Believe that we can provide you with the most suitable equipment and the best service.