What is the extraction process of mustard oil?

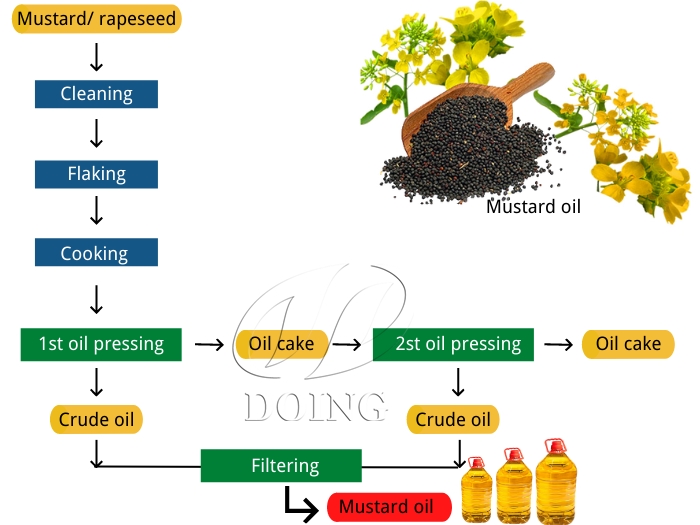

April 8, 2022 15:19/ FAQ/ leave a messageThe extraction process of mustard oil involves removing impurities from the mustard seeds, then adjusting the mustard seeds to the optimal pressing state through a series of processes, and then extracting the oil from the mustard. For mustard oil mill plant, the most cost-effective and widely used method for mustard oil extraction process is mechanical extraction by mustard oil processing machines. Here, I will introduce you how to extract mustard oil step by step in large scale mustard oil mill plant.

In summary, the extraction process of mustard oil consists of five steps, respectively: cleaning, flaking, cooking, pressing, filtering.

Mustard oil extraction process

Mustard oil extraction process

The first step: Cleaning

As an oil crop, mustard seeds inevitably carry some impurities. If the soil, stems and leaves buried in mustard seeds are not removed, it will not only affect the quality of oil and cake, but also reduce the oil yield. There are many ways to clean up, depending on the types of impurities. If the impurities are light, such as grass, stems, leaves, etc., vibrating cleaning screen will be very useful. If it is soil, we need to remove impurities similar to the size of the mustard seeds with the help of a de-stoner machine. If the impurity is iron, we can use magnetic separation machine to remove the magnetic impurities.

The second step: Flaking

Flaking refers to using a single pair of roller rolling machine rolling into thin and uniform billet. By rolling the embryo, the pressing area of mustard is increased, on the other hand, it helps to improve the extraction rate of mustard oil.

The third step: Cooking

Cooking can destroy the cell structure of mustard seeds, denaturate protein, absorb water and expand phospholipid, meet the requirements of pressing, speed up oil production and reduce the content of phospholipid. The effect of cooking directly affects the smooth progress of the whole oil production process, the level of oil yield and the quality of oil products and cakes.

Mustard seeds roaster machine

Mustard seeds roaster machine

The fourth step: Pressing

During cooking oil pressing workshop, the most widely used oil press machine is screw cooking oil press, it has simple structure, high pressure, can continue to process materials. What's more, it can press a variety of oilseeds such as groundnut, soybean, palm kernel, cottonseeds, sesame seeds, castor seeds, etc.

Mustard oil press machine

Mustard oil press machine

The fifth step: Filtering

The final step involves filtering the extracted oil to remove impurities from the oil before the oil is bottled and stored. If want to produce high quality or high-end mustard oil, edible oil refining process is recommended.

Mustard oil filter machine

Mustard oil filter machine

From the above introduction, you should have a general understanding of the extraction process of mustard oil. If you are interested in setting up mustard oil mill plant, please contact us to get the free quotation, equipment list, and technical guidance! Henan Glory Company's engineers together and sales will try the best to offer the most suitable oil production plan based on your budget and requirements!