How the sunflower oil processed? What processes involved in sunflower seed oil production?

March 23, 2022 14:38/ FAQ/ leave a messageSunflower is treasure all over. Sunflower seed kernel has high oil content around 45%~55% and can be used for oil extraction. Sunflower seed oil is called "advanced nutrition" or "health oil" at home and abroad and is a best-selling product in the international market. For more than half a century, the world sunflower seed oil consumption demand has increased rapidly, thus driving the continuous expansion of sunflower seed production scale. Sunflower seed oil production technology is becoming more and more mature.

Sunflower seeds and sunflower oil

Sunflower seeds and sunflower oil

Then how the sunflower oil processed? What are the ways to process sunflower oil? Let's keep reading.

There are two ways can be used to process sunflower oil. One is extracting sunflower oil from sunflower seeds by physical pressing with sunflower oil pressing machine, which retains the natural fragrance of sunflower seed oil. The other is to extracting oil from sunflower seed cake by the principle of solvent and oil dissolution, which also named solvent extraction method. After solvent extraction process, the residual oil rate of sunflower seed cake was less than 1%, which improved the yield of sunflower seed oil. Let's take a look at the detailed production process of these two sunflower oil extraction methods.

1. Produce sunflower seed oil by physical pressing;

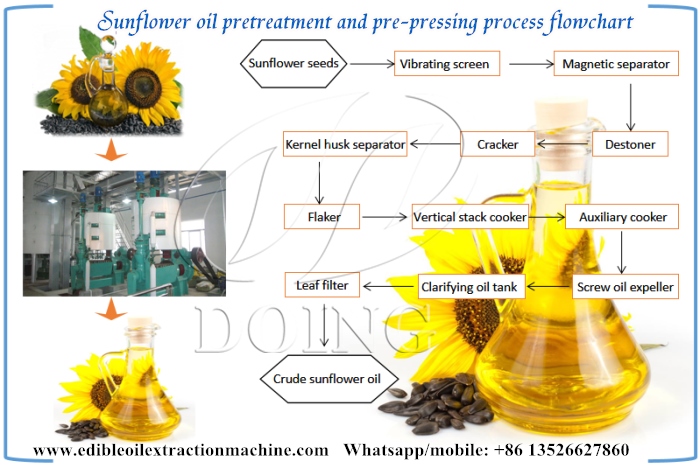

First, we need to use cleaning equipment to remove impurities from sunflower seeds. Common cleaning equipment includes magnetic separator, cleaning screen and stone removal machine.

Then, we need to use a sheller and a kernel and shell separator machine to separate the kernels of sunflower seeds. Sunflower seed shell not only affects the use of sunflower seed oil production equipment, but also absorbs part of sunflower seed oil, resulting in oil loss, so it needs to be removed.

Next, we need to adjust the temperature, humidity and internal structure of sunflower seeds by using flaking roll and cooker, which is more conducive to oil production.

Last but not least, we need to use sunflower seed oil press machine to press sunflower seeds, get sunflower seed oil, if you want to get more oil, you can press it again.

Finally, we need to use plate and filter machine to remove the impurity and part of water of the crude oil.

Recommended reading: Sunflower oil pretreatment & pre-pressing machine

Sunflower oil pretreatment and pressing process

Sunflower oil pretreatment and pressing process

2. Produce sunflower seed oil by solvent extraction method;

The production of sunflower seed oil by solvent extraction method also needs cleaning equipment, sheller, kernel and shell separator machine, flaking roll, cooker, etc., to process sunflower seeds, adjust the internal structure of sunflower seeds, and improve the production efficiency of sunflower seed oil. Then, use a sunflower oil pre-press machine to get sunflower oil and sunflower cake. While, sunflower seed cake needs to be transported to the solvent extraction workshop for further production of sunflower seed oil.

Sunflower Oil Solvent Extraction Plant includes solvent extraction section, miscella evaporation and stripping section, wet meal desolvation section, solvent recovery section.

Recommended reading: Sunflower oil solvent extraction plant

Sunflower oil solvent extraction process

Sunflower oil solvent extraction process

After reading this article, I believe you have a deeper understanding of how the sunflower oil processed? what processes involved in sunflower seed oil production? If you want to start sunflower oil processing business and want to learn more information about sunflower oil processing plant projects, equipment list and price list. Welcome to contact us, Henan Glory Company can supply a wide range of sunflower oil processing machines to meet your needs.