How to work the continuous palm oil refining machine?

April 16, 2019 20:39/ FAQ/ leave a message

Due to palm oil is low cutin cooking oil, in order to have a better refining effect, we adopt Dry-degumming full continuous palm oil refining method to refine palm oil. During palm oil refinery process, the degumming process together with decolorization, and deacidification with deodorization. Compared with common edible oil refining, this dry-degumming full continuous palm oil refining method is more proper for palm oil feature.

Note: Not all the palm oil refining machines are required to adopts dry-degumming full continuous palm oil refining method to refine crude palm oil. If your crude palm oil capacity is very small, less than 10tpd, the palm oil chemical refining methods is more suitable. For large capacity above 30tpd, Dry-degumming full contunuous palm oil refinery method is the best choice.

Continuous palm oil physical refinery process flow chart:

Continuous palm oil refining machine

Continuous palm oil refining machine

How to work the continuous palm oil refining machine?

Firstly, in the decolorization section, crude palm oil mixed with phosphoric acid, and together with white clay pumped into vacuum decolorization(bleaching)tower. Then the decolorized oil comes to the vibrating filter. The valves are automatic swiched. Filtered oil is pumped into deodorization section.

Continuous palm oil physical refining machine——decolorization section

Continuous palm oil physical refining machine——decolorization section

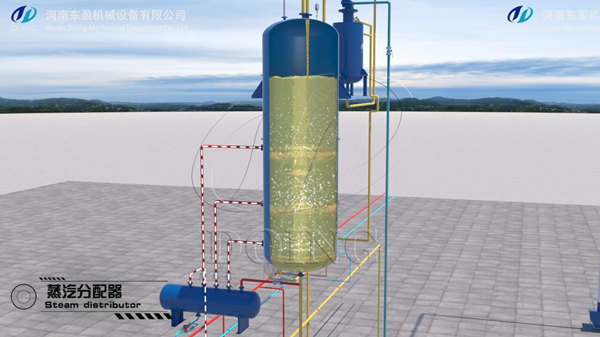

Secondly, After heat exchange, decolored oil comes to packed tower combined type deodorization tower. The free fatty acid is removed in the upper part, and then oil is deodored in the under part.

Continuous palm oil physical refining machine——deodorization and deacidification section

Continuous palm oil physical refining machine——deodorization and deacidification section

Thirdly, after heat exchange again, deodored oil need be cooled to normal tempetature and pump to refined oil tank.

Working principle of continuous palm oil refining machine:

The crude palm oil is pumped to pipe filters; then filtered oil is sent to heat exchanger. Heated oil is mixed with acid in the mixer before going to the reaction tank. After reaction and cooling, the mixed palm oil is pumped into vacuum drier, and then dried oil is heated by a heat exchanger and sent into palm oil decolorization section.

The palm oil to be bleached is pumped to mixed tank and heating tank separately. A proportion of oil to be bleached is pumped into a mixing tank to mix with white clay, and another part of oil to be bleached is pumped to the heater. The mixture and the heated oil go into the bleaching tank to de-colourize.Then, the mixture of oil and white clay is pumped into leaf filter to remove waste clay.

Parallel leaf filters make it possible to perform continuous operation of bleaching. Filtered oil is pumped into the storage tank after being cooled in a heat exchanger and filtered safely.

After palm oil decolorization process, the decolorized palm oil is pumped to deodorization section(Deodorization section is to remove the unpleasant odor from bleached oil). Certain amount of citric acid liquid is added to the oil to be deodorized to chelate the metal ion in oil. The oil then enters a deaeration tank to remove air in the oil by high vacuum. Then oil is pumped into a heat exchanger to raise temperature with hot deodorized oil; palm oil is heated further by mineral oil to raise the temperature to 240℃~265℃. The heated oil goes into the deodorizer tower from the top of flash sector; mixes with the rising steam to strip low molecular organic compound. Oil flows down to the bottom of tower to perform pigment decomposition. The flavor of oil is improved. Oil is pumped into the main sector of deodorizer tower to further remove free fatty acid (FFA). The vapor goes into FFA stripping sector to exchange heat; the condensed low molecular compound goes into the recycling FFA stripping system. The deodorized oil from the bottom of deodorizer tower is pumped out to exchange heat with oil that comes out from the deaeration tank, and then goes to a cooler. Finally, oil is filtered by polished filter. Final product is sent to final oil tank, which can be sold as first class product oil.

[Recommend reading: Palm oil refinery plant ]

If you want to further fractionate refined oil to get palm olein and stearin, after palm oil refining process, palm oil can start fractionation section in the near workshop.