What is the processing process of different oil seeds?

July 1, 2022 10:50/ FAQ/ leave a messageOil seeds processing generally refers to the process of extracting cooking oil from oil seeds. The whole processing process begins with oilseed harvesting, and ends with oil filling.The machines used in oil seeds processing process called oilseeds pretreatment and pre-pressing machine includes cleaning machine, cracking machine, crushing machine, softening machine, flaking machine, cooking machine, pressing machine, filtering machine and crude cooking oil filling machine.

Cooking oil processing machine

Cooking oil processing machine

Different kinds of oil seeds have different oil content and different physical properties. So the pre-treatment process varies slightly from one kind of oil seed to another. But most oil seeds pre-processing includes cleaning, cracking, crushing, flaking, cooking or puffing. Below are typical oil seed pre-treatment processes of soybeans, canola seeds, sunflower seeds, peanut, and cottonseeds.

1, Soybean oil processing process;

The standard soybean pretreatment and pressing process mainly includes cleaning, crushing, softening, flaking, cooking, pressing and filtering. Each steps has different functions. As the following picture shows:

Soybean oil processing process

Soybean oil processing process

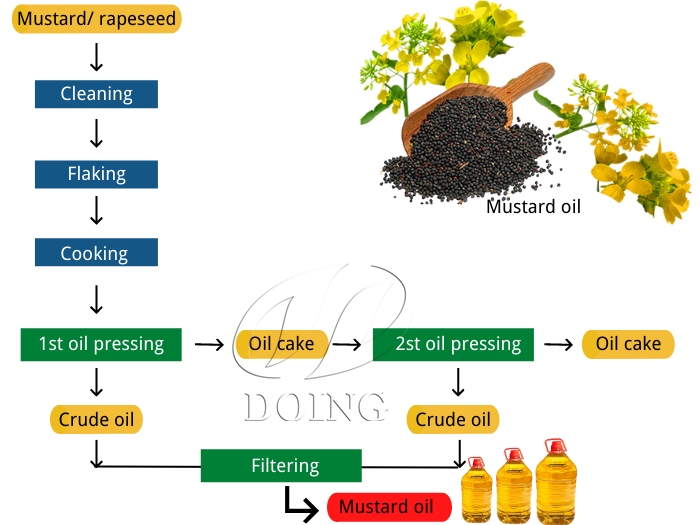

2, Canola seeds oil processing process;

Canola seeds oil pretreatment and pressing process mainly including cleaning, crushing, softening, flaking, cooking, pressing, filtering. Finally, you get crude canola oil and oil cakes. As the following picture shows:

Canola oil processing process

Canola oil processing process

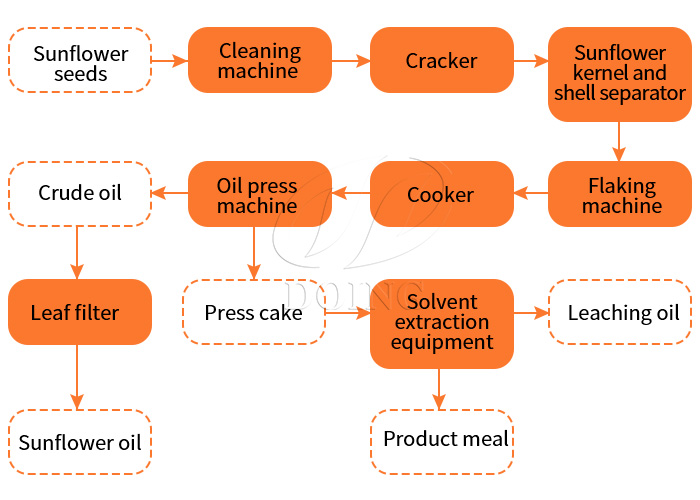

3, Sunflower seeds oil processing process;

Sunflower seeds is a kind of high oil content oil seeds, so the pre-pressing is necessary for making sunflower oil. Through a series of equipment processing, the sunflower seeds are adjusted in the best condition, and then sent into sunflower oil pre-pressing machine to extract part of sunflower oil. The processing process of sunflower seeds includes cleaning, cracking, flaking, cooking, pressing and filtering. [Related reading: Sunflower oil pretreatment & pre-pressing machine ]As the following picture shows:

Sunflower oil processing process

Sunflower oil processing process

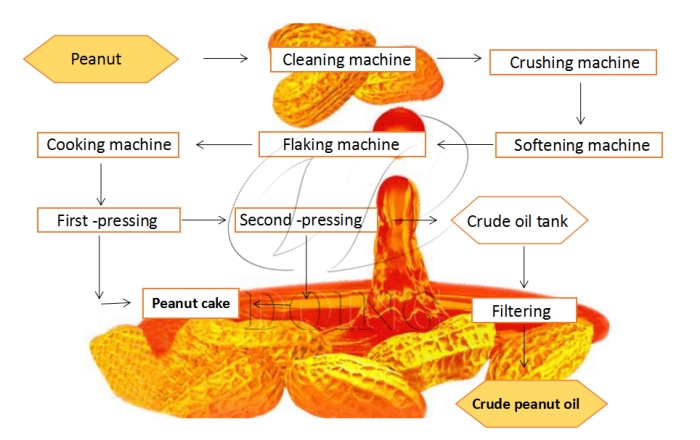

4, Peanut oil processing process;

Peanut is another kinds of high oil content oilseed, the processing steps of peanut pretreatment and pressing: cleaning- crushing- flaking- cooking- oil pressing or pre-pressing- filtering-filling. As the following picture shows:

Peanut oil processing process

Peanut oil processing process

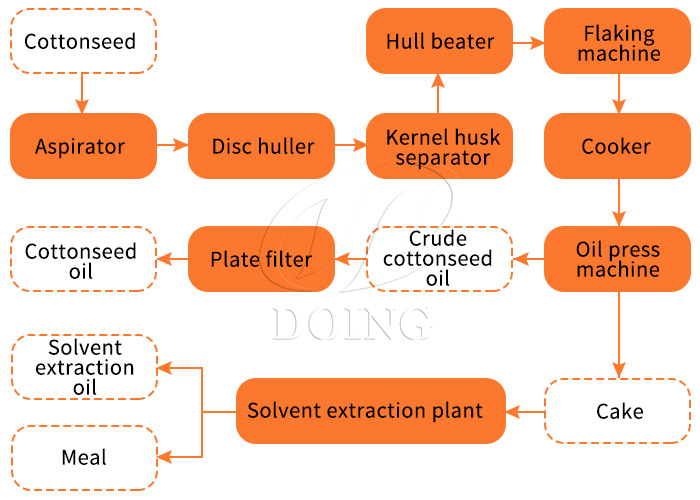

5, Cottonseed oil processing process;

Cottonseed oil pretreatment and pressing process is similar with sunflower oil processing process, mainly includes: cleaning, cracking, flaking, cooking, pressing and filtering. But the equipment used in the cracking section is different. The specific process is as follows:

Cottonseed oil processing process

Cottonseed oil processing process

In order to facilitate customers to more comprehensive understanding of the function of each equipment and each section of whole cooking oil processing plant, Henan Glory Company specially summarized the following content, hoping it is helpful to you.

Large scale cooking oil processing machine

Large scale cooking oil processing machine

Cleaning: Remove impurities in oil seeds, such as leaves, sticks, stones, sand, dirt, spoiled seeds and metal contaminants. The machine used in this process includes magnetic devices, cleaning sieve and destoner.

Oil seeds cleaning machine

Oil seeds cleaning machine

Cracking: Most oilseeds need to remove the shells before oil extracting, since the oil content of shells is less than 1%. Besides, shelling can not only improve the processing capacity of oil extraction equipment, increase the efficiency of oil production, but also can reduce wear of oil expeller. Cracker is commonly used in this process.

Crushing & Flaking: For big-size oil seeds, crushing can reduce its size to benefit flaking. (Friendly reminder: Crushing is always necessary for soybean, peanut, palm kernel, etc.) To reach better oil extraction effect, Flaking process is necessary, flaking presses oil seeds from granular to laminar, which breaks cell tissue of oil seeds and creates beneficial condition for cooking. Flaking also makes oil flows out smoothly when pressing or solvent extraction.

Cooking: Cooking is to wet, heat, steam and to cook flakes to change the internal structure of flakes, including destorying cells, protein solidification and denaturation, etc. All these changes makes oil easy to isolate and also enhance crude oil quality. Cooking pot can be used for processing groundnut/peanut, canola seed, cottonseed, sunflower seed, etc.

Extruding/Puffing (optional):Through extrusion (puffing) by means of expander (extruder), the oilseeds materials will be expanded because of sudden pressure-relief, Meanwhile steam in the material is evaporated all of a sudden, so the material become microporous structure and expanded to irregular particles.

Pressing/Prepressing: This process is to press oil from oil seeds or pretreated material. In general, there are several types of oil press machines for this step, people can choose according to their own actual situation.

Cooking oil pressing machine

Cooking oil pressing machine

This is the details about different kinds of oil seeds processing process. As a professional manufacturer of cooking oil processing machine, Henan Glory can provide cooking oil processing plant designing, manufacturing, testing, delivery, installation, commissioning services. If you are interested in oilseed pretreatment & pressing machines or want to know more about other cooking oil processing process, welcome to contact us.