What are the precautions of ensuring the performance of palm kernel cracker and separating system?

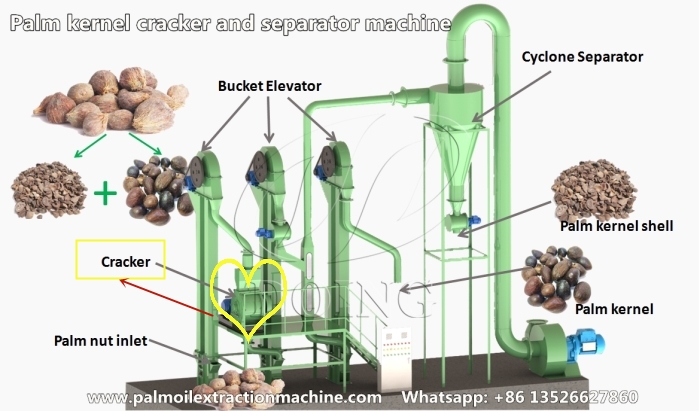

June 28, 2024 15:43/ FAQ/ leave a messageThe palm kernel cracker and separating system is a crucial part of the palm oil milling process. It involves breaking the hard shell of the palm kernel to extract the kernel for further processing into products like palm kernel oil. Ensuring the performance of palm kernel cracker and separating system requires careful attention to the following precautions:

1.Controlling Feed Rate:

Maintaining a consistent and appropriate feed rate into the palm kernel cracker and separating machine to avoid overloading or underutilization. An uneven flow can lead to inefficient palm kernel cracking and shell separating.

2.Monitoring Cracking Efficiency:

Monitoring the efficiency of the palm kernel cracker and separating machine regularly. The palm kernel cracker and separating machine should be set up to crack the shells without damaging the kernels excessively, as this can lead to lower oil recovery and reduced quality of the resulting products. The palm kernel cracker and separating machine produced by our Henan Glory Company can not only achieve a cracking rate of 95-98% and a separation rate of 98%, but also can well ensure the integrity of palm kernels.

The palm kernel cracker and separating machine produced by Henan Glory Company

The palm kernel cracker and separating machine produced by Henan Glory Company

3.Regular Maintenance:

Regular maintenance of palm kernel cracker and separating system is crucial to prevent breakdowns and ensure smooth operation. This includes regular cleaning, lubrication, and replacement of worn parts.

4.Adjustments and Settings:

Makeing precise adjustments to the palm kernel cracker and separating machine's settings based on the size and moisture content of the kernels being processed. This includes adjusting the speed, pressure, and spacing of the components to achieve the desired cracking and separating efficiency.

5.Controlling Temperature:

Monitoring and controlling the temperature during the palm kernel cracking process. High temperatures can damage the palm kernel oil, affecting its quality and reducing its shelf life.

6.Training and Supervision:

Ensuring that operators are well-trained in the use of the palm kernel cracker and separating machine and understand the importance of maintaining performance standards. They should be familiar with the palm kernel cracker and separating machine, safety procedures, and troubleshooting techniques to address any issues that may arise during operation.

The palm kernel cracker and separating machine

The palm kernel cracker and separating machine

By following these precautions, a palm oil mill can ensure that its palm kernel cracker and separating system operates at peak performance, contributing to overall efficiency, product quality, and profitability. If you have any other questions about palm kernel cracker and separating system, please feel free to contact us and we will provide you with one-to-one professional answers.