How to process sunflower seeds into sunflower oil?

July 26, 2024 17:12/ FAQ/ leave a messageSunflower oil is a kind of oil extracted from sunflower seeds. It is loved by consumers for its golden color, clear and transparent appearance and fragrant smell. But processing sunflower seeds into sunflower oil is a rigorous and delicate process behind it. Here’s a step-by-step guide about sunflower oil processing process:

1. Raw material selection for sunflower oil processing process

Sunflower seeds are divided into edible sunflower seeds and oil sunflower seeds. Among them, oil sunflower seeds have an oil content of 45-50%, which is the preferred raw material for sunflower oil processing process and one of the main oils in many countries.

Edible sunflower seeds and oil sunflower seeds

Edible sunflower seeds and oil sunflower seeds

2. Pretreatment process for sunflower oil processing process:

(1) Cleaning: This process requires some sunflower oil processing machines, such as vibrating cleaning sieves, de-stonner and magnetic separators. The purpose is to remove impurities in sunflower seeds, such as iron filings, stones and other metal impurities.

Sunflower oil cleaning machines

Sunflower oil cleaning machines

(2) Shelling: This process requires a shelling machine. The purpose is to remove the shell of sunflower seeds.

(3) Kernel-shell separation: This process requires a kernel-shell separation screen. The purpose is to separate the peel and seeds. Unshelled sunflower seeds will automatically return to the shelling machine.

(4) Cooking: This process requires a roasting machine. The purpose is to control the moisture and temperature of the sunflower seeds, so as to be more conducive to obtaining high-quality sunflower oil.

3. Pressing process for sunflower oil processing process:

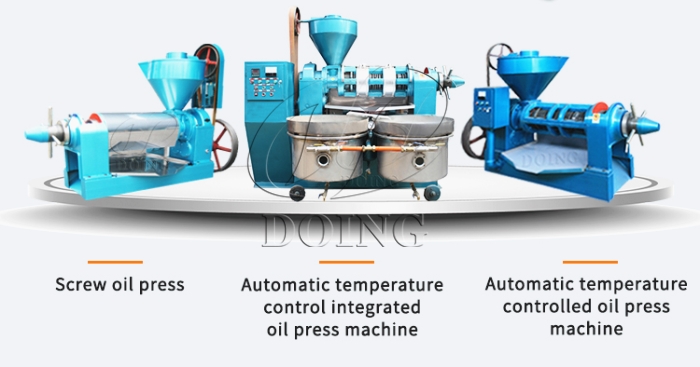

This process requires a sunflower oil pressing machine. The purpose is to press the sunflower seeds to extract sunflower oil. In this regard, Henan Glory Company provides a variety of sunflower oil pressing machines, including screw sunflower oil pressing machine and integrated sunflower oil pressing machine. Among them, the integrated sunflower oil pressing machine can not only press sunflower seeds but also filter sunflower oil directly.

Sunflower oil pressing machines

Sunflower oil pressing machines

4. Filtering process for sunflower oil processing process:

This process requires a plate and frame filter. The purpose is to remove any remaining solids or impurities in the sunflower oil.

Sunflower oil filtering machines

Sunflower oil filtering machines

5. Storing process for sunflower oil processing process:

(1) Bottling: Bottle the filtered sunflower oil in a clean, dry, preferably dark glass bottle to protect it from light.

(2) Storing: Store the sunflower oil in a cool, dark place. While refrigeration is not necessary, doing so will extend its shelf life.

By following above sunflower oil processing processes can only extract crude sunflower oil. If you want to obtain clear and transparent refined sunflower oil, you also need to carry out sunflower oil refining process and sunflower oil dewaxing process. It’s worth noting that processing sunflower seeds into sunflower oil may vary depending on the machines and resources you have available. If you have any questions about processing sunflower seeds into sunflower oil, welcome to consult Henan Glory Company!