20tpd peanut oil refining machine

20tpd peanut oil refining machine

20tpd peanut oil refining machine

Usually 20tpd peanut oil refining machine often adopts semi-continuous edible oil refining technology to refine crude peanut oil. After peanut oil degumming, neutralizing, bleaching and deodoring process. The refined oil has high quality and is good for long time storage.

This 20tpd peanut oil refining machine not only refine crude peanut oil , but also refine other crude edible oil, such as rapeseed oil, cotton seed oil, soybean oil, canola oil, palm oil, palm kernel oil, coconut oil, etc. Besides, semi continuous peanut oil refining machine, we also offer 1-10tpd small scale peanut oil refining machine and 30-600tpd fully-continuous peanut oil refining machine.

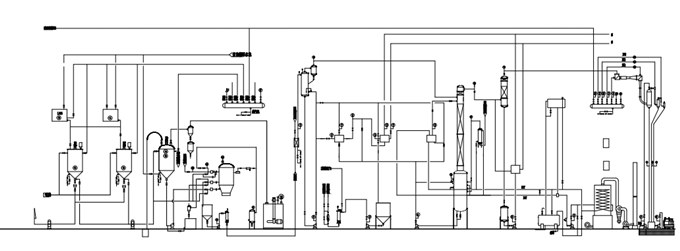

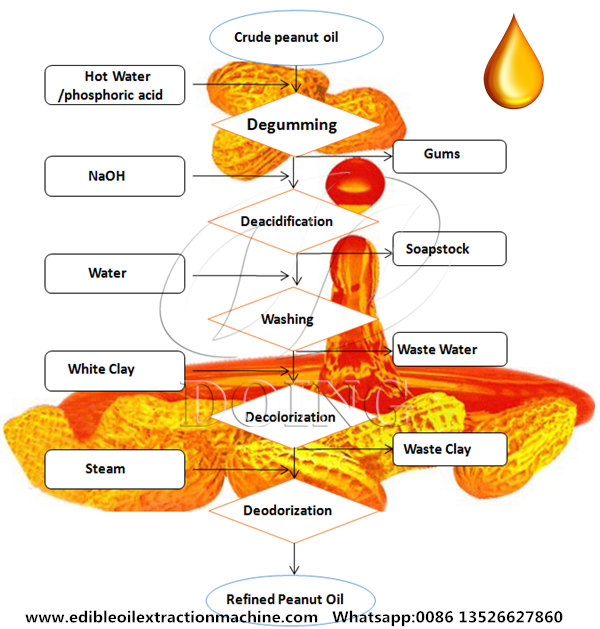

Flow chart of 20tpd peanut oil refining machine:

Flow chart of peanut oil refining machine (this is sem-continuous peanut oil refining process flowchart)

Flow chart of peanut oil refining machine (this is sem-continuous peanut oil refining process flowchart)

20tpd peanut oil refining process:

Crude peanut oil→ Degumming process → Deacidification process → Decolorization process → Deodorization process → Refined peanut oil (final peanut oil)

Peanut oil refining process flowchart

Peanut oil refining process flowchart

Process of 20tpd peanut oil refining machine:

Degumming process:

The purpose of Degumming is to remove Gums. All oils have hydratable and non-hydratable gums.

a. Water Degumming: Hydratable gums are removed by treating oils with water and separating the gums. The gums can be dried to produce lecithin.

b. Acid Degumming: Non-Hydratable gums are removed by treating oils with acids and separating the gums.

Neutralizing process:

The purpose of Neutralizing is to remove Free-Fatty Acids (FFAs). Traditionally, FFAs are treated with caustic soda (NaOH). The reaction produces Soaps which are separated from the oil. Because trace amounts of soaps remain in the oil, the oil is either washed with water or treated with Silica.

But if you don't want to use caustic soda (NaOH) to remove Free-Fatty Acids (FFAs). You can choose to use physical refining method to dispose FFA. During peanut oil physical refining process, The FFAs in peanut oil are evaporated from the oil under high temperature and vacuum.

Note:

Physical Refining process is preferred because:

(a) it does not produce soaps;

(b) it recovers fatty acids that provide better cost recovery;

(c) there is smaller yield loss compared to caustic refining—especially for oils with higher FFAs;

(d) it is a chemical-free process.

Bleaching process:

The purpose of Bleaching is to remove color pigments contained in Vegetable Oils. The oil is treated with Bleaching Clays that adsorb the color pigments. The clay is filtered and the clean bleached oil is stored for further processing. Process flow diagram is attached.

Deodorizing process

The purpose of Deodorizing is to remove odor substances. The peanut oil is subjected to steam distillation under high temperature and vacuum to evaporate all odor substances. The resulting deodorized oil is almost bland and tasteless.

This is semi-continuous peanut oil refining machine

This is semi-continuous peanut oil refining machine

Why so many people choose to buy peanut oil refining machine from Henan Doing Company?

1. Customized capacity. We customize peanut oil refining machine as per your requirement for the capacity.

2. Flexible usage. The peanut oil refining machine can work independently or together with whole peanut oil production line;

3. Excellent after-sales service. We provide two engineers after your receipt of equipments for on site installation, debugging and training.

As a professional manufacturer and supplier of edible oil refining machine. Henan Doing Company will customize the edible oil refinery process and solution for each of customer depending on their specific situation and needs.