Peanut cake solvent extraction machine

The peanut cake solvent extraction machine is part of peanut oil mill plant which is designed to extract oil from peanut cake.Our peanut cake solvent extraction machine adopt new type energy saving technolog, which can reduce steam, water and electric consumption. What's more, the peanut cake solvent extraction machine can ensure good quality peanut oil. And the PLC system make the peanut cake solvent extraction machine easy to operate.

Peanut cake solvent extraction machine

Peanut cake solvent extraction machine

Main process of peanut cake solvent extraction process:

Solvent extraction system→D.T.D.C system→Condenser system→Recovery system

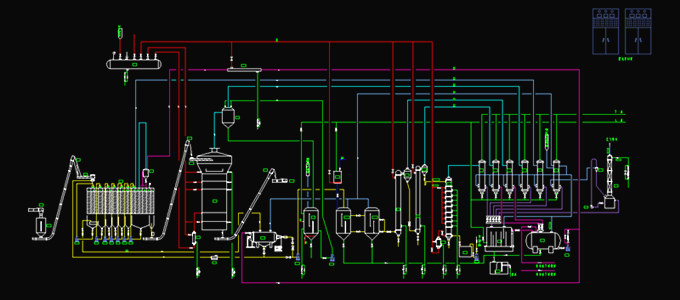

Peanut cake solvent extraction process flowchart

Peanut cake solvent extraction process flowchart

Main equipment of peanut cake solvent extraction machine:

(1) Solvent pumps: continuously spray solvent to the rotary-type extractor;

(2)Rotocel extractor: Spray and soak the pre-pressed cake with solvent so that oil fats can be dissolved in solvent(form miscella). After processing, you can get wet meal and miscella (mixed oil).

(3)DTDC: used to separate the solvent from the wet meal.

(4)Miscella tank 1st: pump the miscella (oil with solvent) in to the miscella 1st , and then add 10% saline water to it. The phospholipid and impurities in the miscella will react with the saline wter,at last the reactant precipitate, reaching the goal of purifying.

(5)Miscella tank 2nd: the purified miscella will be pumped into it.

(6)Miscella stripping: it will remove the remaining solvent in miscella. And the solvent will be discharged to condenser for recycling.

(7)Condensers: used to cooling the solvent gas separated from the wet meal and miscella for recycling.

Peanut cake solvent extraction machine

Peanut cake solvent extraction machine

Working principle of peanut cake solvent extraction machine:

a. The peanut cake (for pretreatment) is sent to rotary extraction by the scraper conveyor. The crude oil will extracted by the solvent or mix oil. After this step, we will get meal and mix oil

b. Meal is send to toaster. Through the toaster, the solvent in the meal will seperate from the meal. The solvent goes to condenser and is recycled to rotary extraction.

c. After the mix crude oil from the rotary extraction enters into 1st evaporator and 2nd evaporator, most of the solvent in the crude oil is separated.

d.The mix crude oil from 2nd evaporator goes to stripping tower and almost all the solvent is separated. From the stripping tower, we can get crude oil and solvent. The solvent is sent to condenser and is recycled to rotary extraction.

Technical parameters of peanut cake solvent extraction machine:

| 1 | Residualoilinmeal | ≤1%(different from various oilseeds) |

| 2 | Solventconsumption | ≤1.5-3Kg/T(hexane) |

| 3 | moistureandvolatilematter | ≤0.30% |

| 4 | Powerconsumption | ≤15KWh/T |

| 5 | Steamconsumption | ≤280Kg/T(0.8MPa) |

| 6 | Finishedmealmoisture | ≤10-13%(adjustable) |

| 7 | Residualsolventinfinishedmeal | ≤300PPM(qualifieddetonatedexperiment) |

Features of peanut cake solvent extraction machine:

1,Adopting negative pressure evaporation can ensure excellent oil quality

2,Extraction system is highly adaptable and can adapt to different raw materials

3,All peanut cake solvent extraction machine is provided with exhaust gas absorption systems with excellent absorption effect

4 ,Full energy saving design utilizes heat energy for many times and saves steam consumption.

Penaut cake solvent extraction machine

Penaut cake solvent extraction machine

According to the customer’s various conditions. We can provide suitable peanut cake solvent extyraction plant engineering plan. And we can offer custom-made design. Meanwhile we can supply various configurations according to your needs. At this very moment, do you want to start a peanut oil processing business like this? If yes, we Henan Doing Company can help you. Let's do it.