Sunflower oil mill plant

Sunflower seeds introduction:

Sunflower seed was the third largest source of vegetable oil worldwide, following soybean and palm. Europe and the USSR produce over 60% of the world's sunflowers.Sunflower seed is a source of high quality oil used for cooking.The oil content of sunflower seed is 45%.Usually,after pressing, the residual in cake is about12%-16%.After extraction process,the residual can lower than 1%. In ordert to get more sunflower oil from sunflower seeds ,we need to start a sunflower oil mill plant project.

In ordert to get more sunflower oil from sunflower seeds ,we need to start a sunflower oil mill plant project.

In ordert to get more sunflower oil from sunflower seeds ,we need to start a sunflower oil mill plant project.

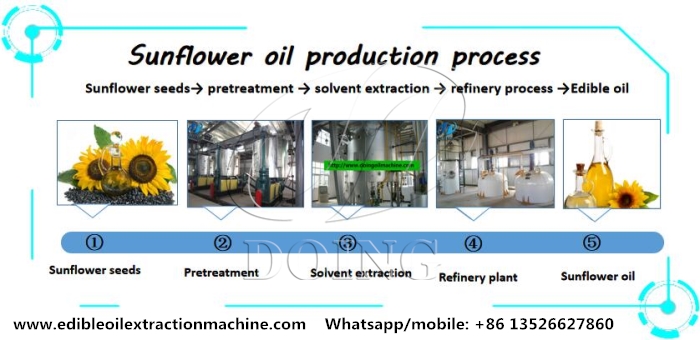

Sunflower oil mill plant introduction(Sunflower oil production line for sunflower oil factory to produce refined cooking oil):

We are professional sunflower oil mill plant manufacturer. We can supply complete set of sunflower oil processing machine, which include sunflower oil press machine, sunflower oil solvent extraction machine and sunflower oil refining machine.The whole sunflower oil mill plant can also process other vegetable plants includes peanut, cotton seeds, soybean seeds, corn seeds, palm kernels and sesame seeds. Sunflower oil mill plant price is depending on the capacity you required.

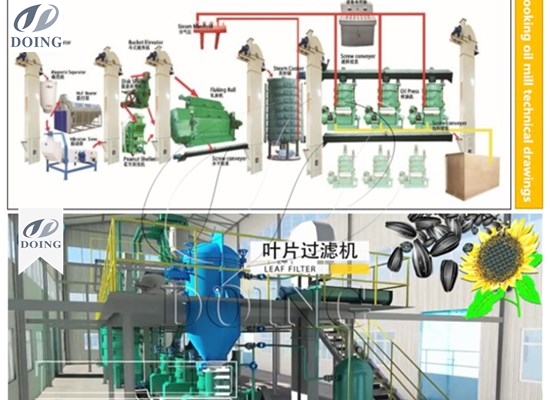

Complete set sunflower oil processing machine

Complete set sunflower oil processing machine

1. Sunflower oil pretreatment and pre-press machine introduction:

Sunflower oil pretreatment process generally refers to the process of extracting oil from oil seeds. The whole processing begins with sunflower seeds cleaning, and ends with oil pressing.The sunflower oil pretreatment and pre-press plant include cleaning section, husking section, flaking section, softening section, cooking section and oil press section.

Sunflower oil pretreatment and pre-pressing machine

Sunflower oil pretreatment and pre-pressing machine

Sunflower oil pre-press steps:

First, using magnetic roller, de-stoner and cleaning machine to remove metals, small stones , impurities from sunflower raw seeds.

Second, using husking machine to remove husks, separating screen to separate husk and sunflower kernel.

Third, cooking sunflower seeds ready for oil pre-press.

Fourth, pre-pressing sunflower seeds, here only pre-press part of sunflower oil , oil residue inside cake (about 12-16%) will be extracted in oil solvent extraction process. After pre-pressed, the crude sunflower oil will be delivered directly to sunflower oil refining workshop, and pressed cake to oil solvent extraction workshop.

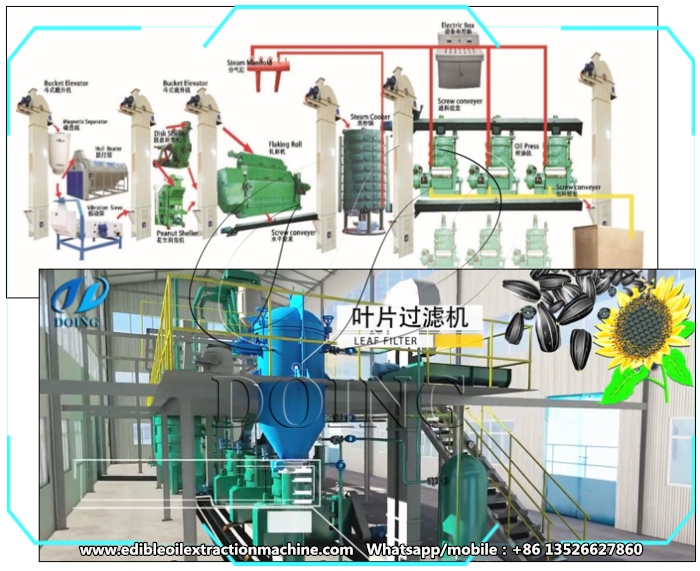

2. Sunflower oil solvent extraction plant introduction:

Sunflower oil solvent extraction is a process of solid-liquid extraction, by means of non-polar solvents. It is widely applied in oil extracting of low oil content materials and pre-pressed oil cakes of high oil content materials. Sunflower oil solvent extraction plant is featured of high yield of oil extraction. The capacity of solvent extraction plant ranges from 20MT to 1000MT.

Sunflower oil solvent extraction plant is the most used machine in sunflower oil processing process

Sunflower oil solvent extraction plant is the most used machine in sunflower oil processing process

Sunflower oil solvent extraction steps:

First, using solvent to extract oil from sunflower oil cake inside rotocel extractor, final products are mixed oil and wet meal.

Second, the mixed oil will pass through three evaporators to make solvent inside transform into gas , and solvent will be recovered through condensers and reused. These three evaporators are not with same size , the first evaporator is bigger than other two because there are more solvent inside mixed oil in the beginning . After evaporated, we will get crude sunflower oil ready for sunflower oil refining.

Third, the wet meal will be delivered to desolventizer to dry and be separated with solvent . The dry meal will be packaged for sale as animal feed.

Note: Sunflower oil solvent extraction plant is more and more important in cooking oil processing , because oil residue inside meal is less than 1% much less than oil residue inside cake without extraction.

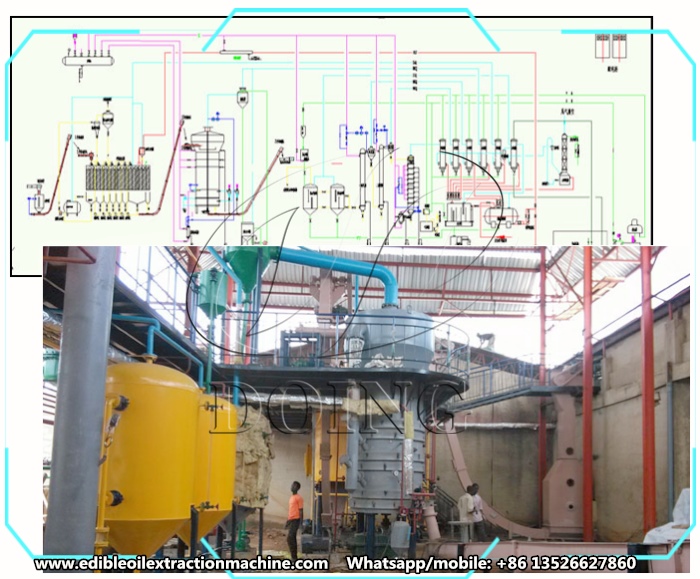

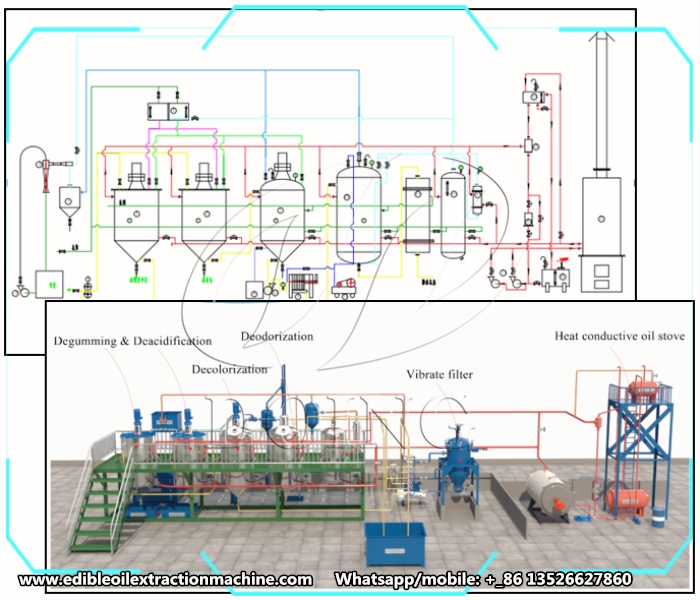

3. Sunflower oil refining machine introduction:

The crude sunflower oil getting from oil pressing or extraction plant certainly contain different amounts of non-oil impurities, such as mechanical impurities, free fatty acid, colloid, pigment, stink substances, moisture and wax, etc. These impurities will directly change the oil’s color, smell, taste, transparency, stability degree and nutrition, which not only affect the edible value, but also make the oil easy to deteriorate when storing.

So in order to get high qulaity sunflower oil, the sunflower oil refining process will be essential. Henan Doing Company is the professional manufacturer of sunflower oil refining machine. We will customize the oil refinery process and solution for each of customer depending on their specific situation and needs.

Sunflower oil refining process flowchart and small scale sunflower oil refining machine

Sunflower oil refining process flowchart and small scale sunflower oil refining machine

Sunflower oil refining steps:

First , hydrated degumming, mainly is to remove phosphatide inside crude sunflower oil in order to reduce oil loss and improve quality of oil .

Second, alkali refining, using alkali to neutralize free fatty acid which we can get the by-product - soapstock. The soapstock is also of great value which is used for making soap.

Third, Vacuum decoloring, using bleaching clay to absorb darker colorant inside crude oil.

Fourth, Vacuum deodorization, using high temparature to remove the impurities and bad smell.

Fifth, dewaxing is using low temperature to freeze wax inside refined oil and then separate wax with plate and frame filter.

Henan Doing Company machinery has rich experience in sunflower oil processing machine installing and producing, scientific management methods, complete quality assurance system, which guarantee us to finish our each sunflower oil mill plant project reliably.