What are the steps of making sunflower oil in edible oil mill plant?

July 31, 2021 15:45/ FAQ/ leave a messageSunflower seed is the fourth largest source of vegetable oil worldwide, following palm fruit, soybean and rapeseed. Sunflower seed is a source of high quality oil used for cooking.The oil content of sunflower seed is 50%-65%. Usually, after pressing and solvent extraction process,the oil residual will be lower than 1%. In order to get more sunflower oil from sunflower seeds ,we apply complete set of sunflower oil processing machine, which including sunflower oil press machine, sunflower oil solvent extraction machine and sunflower oil refinery machine. Now I will introduce the steps of making sunflower oil in edible oil mill plant.

Sunflower seeds

Sunflower seeds

In general, sunflower oil production line includes three sections: sunflower oil pretreatment and pressing section, sunflower oil solvent extraction section and sunflower oil refining section. Each section has a complete and unique set of steps dedicated to them. Taking large scale sunflower oil production line as an example. All machines can be customized according to your requirements.

Complete set of sunflower oil processing machine

Complete set of sunflower oil processing machine

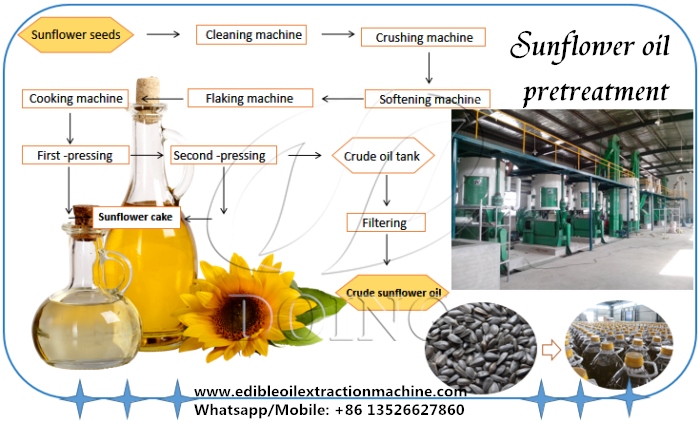

Section one: Sunflower oil pretreatment and pressing machine

The whole processing begins with sunflower seeds cleaning, and ends with oil pressing. The workflow of pretreatment and press section is cleaning--husking----flaking--softening--cooking--pressing. In order to get high quality sunflower oil and improve oil yield, firstly, we need to use cleaning machine and husking machine to remove impurities in sunflower seeds and separate sunflower shell to get pure sunflower seeds. Next, we need to use crushing machine to make the size of peanuts smaller, increasing the surface area of peanuts, which is conducive to the transfer of temperature and moisture during softening. Then we need to use flaking machine, softening machine and cooking machine to regulate moisture and temperature of sunflowers and change sunflower seeds molecular structure. After finishing the above steps, the sunflower seeds will reach the best situation of pressing. All prepared sunflower seeds will be sent to sunflower oil press machine to squeeze out sunflower oil.

Sunflower oil pretreatment and pressing process flow chart

Sunflower oil pretreatment and pressing process flow chart

Section two: Sunflower oil solvent extraction plant

It is widely applied in pre-pressed oil cakes of high oil content materials. Generally, by using the extraction way, the oil residue will be lower than 1%. The workflow of sunflower oil solvent extraction section including extracting, desolventising, evaporating and stripping, condensing and recovering. First, using organic solvents to extract oil from pressed sunflower oil cake inside oil extractor, final products are mixed oil and wet meal. Second, the mixed oil will pass through three evaporators to make solvent inside transform into gas, and organic solvents will be recovered for reuse. After evaporated, we will get crude sunflower oil ready for oil refining. Third, the wet meal will be delivered to desolventizer to dry and be separated with organic solvent. The dry meal will be packaged for sale as animal feed.

Sunflower oil solvent extraction process flow chart

Sunflower oil solvent extraction process flow chart

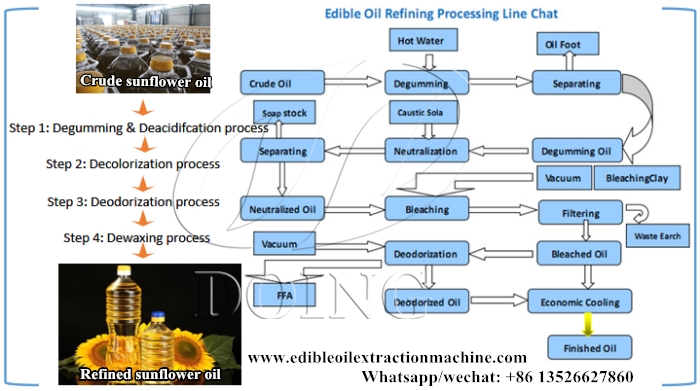

Section three: Sunflower oil refinery plant

The steps of sunflower oil refinery plant is a little different with other vegetable oil refining, because sunflower oil contains too much wax, then except normal vegetable oil refining process, we need add winterization process to keep oil transparent and clear after sunflower oil refined. Firstly, degumming and deacidification process is a necessary step for the production of cooking oil products. It aims at removing the the gum and free fatty acid in the crude sunflower oil. Next, due to the crude sunflower oil is dark color, so normally we will use active clay to make the oil color become clear and light. And then we will use the leaf filter to filter the oil and separate the waste clay. And then the next step is deodorization, steam is injected into the deodorization tower, the FFA (free fatty acids) and other undesirable volatiles will be taken away by the stripping steam.This step aims to remove the bad smell of the oil. Lastly, winterization is the special treatment for sunflower oil, cooling sunflower oil, high melting point component will crystallize, through filtration process, the refined sunflower oil is divided into liquid and solid to achieve different product uses.

Sunflower oil refinery process flow chart

Sunflower oil refinery process flow chart

In fact, the choice of sunflower oil processing machine largely depend on your requirements and the daily processing capacity of your oil mill. As a best sunflower oil processing machine manufacturer in China, Henan Doing Company with a wealth of experience in designing and manufacturing various kinds of sunflower oil processing machine. Besides, we can supply small scale sunflower oil extraction machine with capacity 5-30tpd, we also supply medium sunflower oil extraction machine with capacity 30-500tpd. No matter what capacity your production is, we can customized the reasonable sunflower oil production line according to your output. Please contact us if you are planning for setting up a sunflower oil mill plant!