What machines are used in groundnut oil processing process?

July 31, 2021 15:26/ FAQ/ leave a messageGroundnut is known for its richness in protein, fat, sugar, vitamins and minerals, and its nutritional value is by no means lower than that of milk, eggs or lean meat. Besides, groundnut is a kind of oil crops with high oil content, and the market demand is very large, regardless of regional restrictions. Through a series of processing of peanuts, tasty and brightly colored groundnut oil will be obtained. Considering the above several factors, more and more merchants have realized the huge market potential of groundnut oil processing business. They intend to set up a groundnut oil processing plant in order to expand their business and increase their profit. However, they don’t know what machines are needed due to the lack of knowledge on groundnut oil processing process. In order to solve their confusions, I will introduce the machinery required in the process of pressing groundnut oil.

Complete set of groundnut oil processing machine

Complete set of groundnut oil processing machine

In general, groundnut oil production line includes three sections: groundnut oil pretreatment and pressing section, groundnut oil solvent extraction section and groundnut oil refining section. Each section has a complete set of machinery dedicated to them.

Groundnut oil pretreatment and pressing section

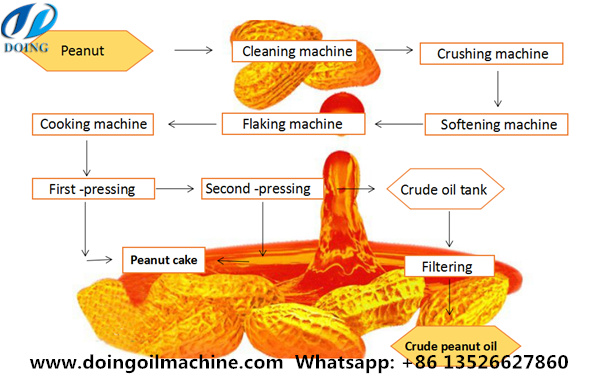

Pretreatment and pressing section is the basic part of the groundnut oil plant, which includes a series of steps such as cleaning, husking, crushing, softening, flaking, cooking and pressing. Its purpose is to remove various impurities in the peanuts, adjust the moisture and temperature of the peanuts, and improve the internal structural state of the peanuts for the extraction of groundnut oil in the pressing stage. The complete set of equipment for groundnut oil involves cleaning machine, husking machine, kernel and shell separating machine, flaking machine, cooking machine, pressing machine and filter machine to obtain crude groundnut oil.

Pretreatment and pressing section workflow of groundnut oil processing plant

Pretreatment and pressing section workflow of groundnut oil processing plant

Groundnut oil solvent extraction section

The groundnut oil solvent extraction plant is one of the most important equipment in the groundnut oil mill plant. Generally, by using the extraction way, the oil residue will be lower than 1%. Groundnut oil solvent extraction plant consists of extraction system, D.T.D.C system, condenser system and recovery system. It involves a series of steps, such as extracting, removing the solvent nature, evaporating, stripping and solvent recycling. Extraction process is the process, which means the separation oil from seeds. The pre-processed seeds are treated in a multistage counter current process with solvent. Then oil and solvent are separated by distillation. The solvent going into the extraction recycle process and the crude oil is ready for a next step.

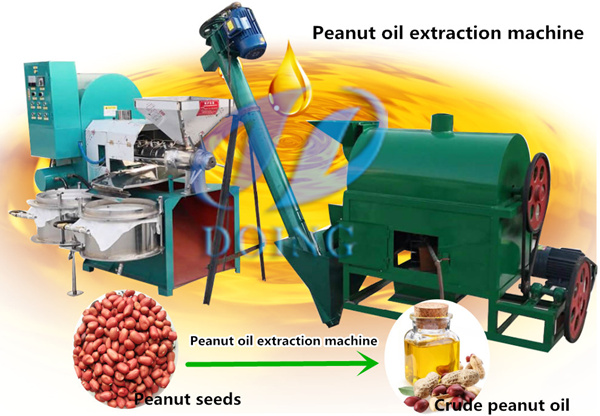

Groundnut oil extraction machine

Groundnut oil extraction machine

Groundnut oil refining section

Groundnut oil refinery plant can refine crude groundnut oil and get standard groundnut oil. The oil obtained from pressing or solvent extraction process always contains impurities such as phospholipids, FFA, pigment and other impurities. In order to make the oil edible, the impurities must be taken out. So the groundnut oil refinery plant is necessary. Groundnut oil refining process always including the following steps: degumming, deacidification, decolorization and deodorization. In the entire groundnut oil refining process, a lot of refining equipment can also be used, such as refining pot, bleaching pot, deodorization pot, vacuum filter, heat conduction oil furnace system, etc.

The above belong to a complete set of groundnut oil production line. In fact, the choice of groundnut oil processing machine largely depend on your requirements and the daily processing capacity of your oil mill. If your daily processing capacity is relatively small and your oil quality requirements are not high, then having an oil press is sufficient. It is suggested that you should consult professional manufacturer to ensure all machines can be customized according to your requirements.

Henan Glory Company is a professional manufacturer of oil processing equipment. We can supply small scale, medium and large scale groundnut oil extraction machine with capacity 5-30tpd, 30-500tpd and 500-2000tpd as well as free and skilled technical guidance. No matter what capacity your production is, we can customized the reasonable peanut oil production line according to your output. I believe that Henan Glory Company will be your first choice. Just contacts us!