How do you extract cooking oil from peanuts at edible oil plant?

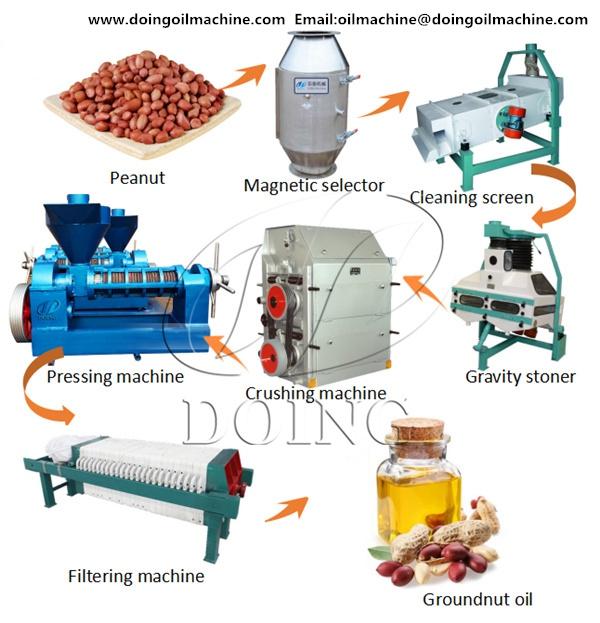

July 31, 2021 15:41/ FAQ/ leave a messageThe extraction of peanut oil is a complicated process. In general, peanut oil production line includes three sections: peanut oil pretreatment and pressing section, peanut oil solvent extraction section and peanut oil refining section. Today, I will mainly introduce the first section --peanut oil pretreatment and pressing section.

Pretreatment and pressing section is the basic part of the peanut oil plant, which includes a series of steps such as cleaning, husking, crushing, softening, flaking, cooking and pressing. Its purpose is to remove various impurities in the peanuts, adjust the moisture and temperature of the peanuts, and improve the internal structural state of the peanuts for the extraction of edible oil in the pressing stage.

Peanut oil extraction machine

Peanut oil extraction machine

Removing the impurities in the raw material

Peanuts in the process of harvesting and transportation will inevitably be mixed with impurities. Remove impurities such as leaves, sticks, stones, dirt, metal contaminants, etc. This process is commonly referred to cleaning machine, such as magnetic selector, de-stonner and vibrate cleaning sieve.

Separating shells from nuts

Most oilseeds need to remove the shells before oil extracting, since the oil content of shells and hulls is less than 1%. Besides, husking can not only improve the capacity of oil extraction equipment, increase the efficiency of oil production, but also can reduce wear and tear of oil press machine. Therefore, it is an important steps for shelled oilseeds, like peanuts, sunflower seeds, cotton seeds, etc., which are processed by the husking machine to improve the peanut oil yield while also reduce mechanical wear.

Crushing peanut into small granules

Most oilseeds require size reduction prior to oil extraction. Through the crushing machine to make the size of peanuts smaller, increasing the surface area of peanuts, which is conducive to the transfer of temperature and moisture during softening. Crushing machine is not required for all kinds of oilseeds, it focus on big size grain.

Adjusting the moisture and temperature of peanut

Peanuts passed through the softening pot to adjust the moisture and temperature of peanuts to make them soft and increase the plasticity of them to facilitate the subsequent operation.

Flaking the peanuts from granular to flaky

Peanuts enter the flaking roll, which presses the peanuts from granular to flaky, increasing the surface area of the peanuts. It mainly used to destroy seed construction to make the oilseeds flak thinner, for better oil yield.

Cooking the flaky peanut to the best press state

Peanuts enter cooker, after wetting, heating, steaming billet and frying billet and other processing, its internal structure is changed and transformed. Through the regulation of moisture and temperature to make the peanuts oil cells fully destroyed, so that the protein contained in the peanuts are denatured, grease aggregation, viscosity and surface tension are reduced, which is more conducive to enhance the extraction rate of peanuts oil.

Squeezing out peanut oil

Mature billet enters the screw press machine and is pressed to get crude oil and cake. Crude oil comes out from the frying chamber and enters the vane filter to filter the oil residue,crude oil enters the oil tank after preliminary filtration, cake is sold as processing raw material, animal feed or as a raw material to further extract edible oil by solvent extraction.

Peanut oil pretreatment machine

Peanut oil pretreatment machine

Peanut pretreatment and pressing machine is only one major equipment in peanut oil making process. Besides, we also supply peanut oil solvent extraction plant and peanut oil refining plant. No matter what kinds of peanut oil extraction machine do you want to buy, you can find an ideal one.